Custom Aluminium CNC Machining – High Precision Parts

In modern manufacturing, Aluminium CNC Machining has emerged as a preferred technology among product designers and engineers. Aluminium alloys, renowned for their lightweight, high strength, and excellent corrosion resistance, have become an ideal choice across various industries.

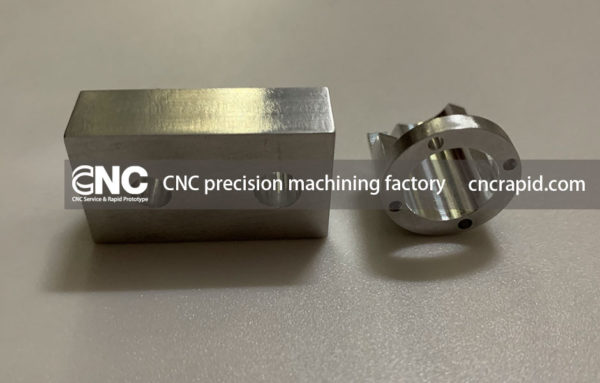

CNC Rapid offers a wide range of CNC machining parts and we are open to manufacturing custom CNC machining parts as per your unique requirements. CNC machining services feature personalized customer service for made-to-order parts and components. We offer turning, milling, drilling, tapping, boring, and grinding for a variety of materials. Learn more about our case studies

Aluminium CNC Machining: Crafting Precise and Efficient Design Solutions

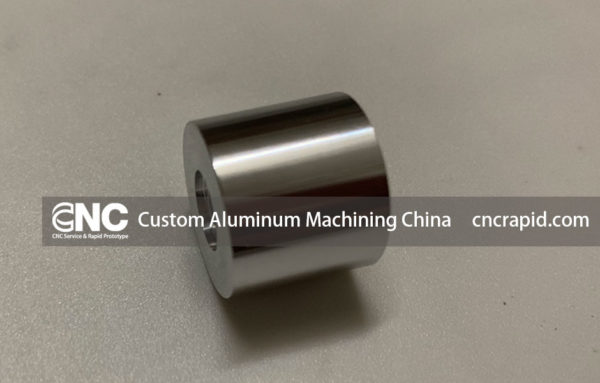

Aluminium CNC machining uses a computer-controlled machine to shape and cut aluminium into specific parts and components. It is precise and efficient, making it popular in various industries. Aluminium CNC machining can create complex shapes and is used to make engine parts, housings, heat sinks, and electronic enclosures. It is important for manufacturing high-quality parts and components with accuracy and consistency.

Aluminium CNC Machining encompasses several steps from raw material to finished product, including milling, turning, drilling, and planing. Precise control of CNC machines enables high accuracy and consistency in production.

Material Selection

Aluminium alloys, with their lightweight, high strength, and excellent corrosion resistance, stand out as an ideal choice for CNC machining. Below are some aluminium alloy grades commonly used in CNC machining, along with their main characteristics and applications:

| Aluminium Alloy | Key Characteristics | Common Applications |

|---|---|---|

| 6061 | Good strength and weldability | Structures, aerospace and automotive parts |

| 7075 | High strength and wear resistance | Aerospace components and high-performance applications |

| 2024 | High strength and heat resistance | Aerospace and military applications |

| 5052 | Good weldability and corrosion resistance | Containers and pipelines |

| 5083 | High strength and good corrosion resistance | Marine applications |

| 6063 | Good extrudability and surface finish | Architectural and structural applications |

Choosing the right aluminium alloy grade is crucial to ensure the performance and durability of the product. For instance, the 6061 alloy, known for its good strength and weldability, is commonly used in manufacturing structures and various automotive parts; while the 7075 alloy, recognized for its high strength and wear resistance, is often utilized in aerospace components and other high-performance applications.

Equipment and Tools

Choosing the right CNC machines and tools is crucial to ensure machining accuracy and efficiency. For instance, using tools specifically designed for aluminium machining can reduce wear and enhance surface quality.

Design Considerations

Designers, while creating designs for aluminium parts, need to consider the material’s characteristics, machining capabilities, and cost. For example, minimizing complex internal structures and sharp edges in the design facilitates machining and subsequent assembly.

Engineering Considerations

Precision and Tolerances

Engineers, while formulating machining plans, need to pay special attention to the precision and tolerances of the parts, ensuring consistency across the entire production batch.

Quality Control

Implementing stringent quality control processes, including real-time monitoring during machining and post-production part inspection, ensures each component adheres to specified standards.

Cost and Efficiency

By optimizing designs and machining processes, along with rational material and tool selection, cost control and efficiency enhancement can be achieved while maintaining component quality.

CNC Machining Services Shop. We specialized in CNC machining services, CNC turning and CNC milling services. Precision CNC machined parts made from turned or milled plastic and metal components. Learn more about our case studies

CNC machining China

DFM Rapid, also known as CNC Rapid, is a leading provider of CNC machining services. We specialize in rapid prototyping and low-volume production. Our team of experienced engineers and machinists can help you bring your ideas to life quickly and affordably. We use the latest CNC machines and software to ensure that your parts are manufactured to the highest quality standards.

Get in Touch

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!