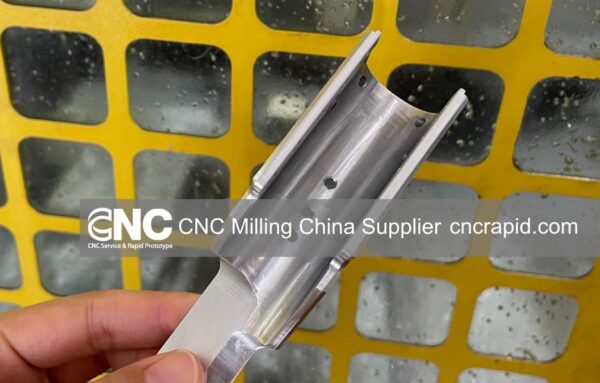

CNC Milling China Supplier. CNC machines can be divided into CNC milling machines and CNC lathes. CNC milling machines can machine complex parts, and CNC lathes generally machine symmetrical cylindrical parts. CNC is commonly used in manufacturing for machining metal and plastic parts. The advantage of CNC milling is that it is accurate, precise, and can provide complex and repeatable parts.

Who are we?

DFM Rapid is a CNC machining shop in Dongguan, China. We have 20 CNC milling and turning machines in our shop. We can provide CNC rapid prototyping and low volume CNC machining. What’s more? Our engineers & machinists have good experience in CNC machining and can provide many good suggestions in CNC manufacturing. So what are you waiting for? Contact us today to get a quote for your CNC projects.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

CNC Turning

Using cutting-edge CNC turning lathe machines, DFM Rapid creates complex custom CNC turned parts from solid metals and plastics with exceptional finishes. From axial and radial holes to flats, grooves, and slots, we can create these parts as quickly as 1 day.

CNC Milling

CNC milling is the preferred process for creating quality and complex geometric pieces used for prototypes and production parts. Our CNC milling process completes CNC milling products as fast as 3~5 days. Our precision CNC tools turn a variety of steels and rigid plastic materials into custom prototypes with impressive accuracy that fulfills your strict requirements.

Benefits of CNC Machining Services

Customers can accrue the following benefits by choosing our CNC machining services.

- Immense Manufacturing Flexibility: As CNC machines are computer controlled, it allows immense machining flexibility. The numerical control programs can be updated easily, allowing the machines to take on more complex machining operations.

- Reduced Costs: The use of CNC machines makes the machining process fast and efficient. It also reduces material wastage. As the machines operate automatically, the need to have multiple operators monitor the process is eliminated, which in turn reduces labor costs. Also, updating the CNC programs is inexpensive.

- Improved Machining Efficiency: CNC machines are capable of producing multiple copies of a single component. As the specifications are inputted via computer, the dimensions of each component will be exactly the same. If an error is found, the machine stops immediately, thus preventing material wastage.

- Uninterrupted Operation: CNC machines are designed for continuous, 24 hours a day operations. Also, with regular maintenance, these machines can be used for product machining projects for many years.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!