Modern manufacturing recognizes CNC (Computer Numerical Control) Rapid Machining Service as a pivotal technology, providing a platform for product designers and engineers to translate design concepts into physical prototypes. This is achieved by integrating computer technology, automatic control technology, testing technology, and machinery manufacturing technology. Recognized as a significant achievement in the advanced manufacturing of the 20th century, CNC Rapid Machining Service not only enhances precision and efficiency in manufacturing but also enables the fabrication of complex parts.

The Core Value of CNC Rapid Machining Service

Designers and engineers often face numerous challenges in the process of converting design concepts into physical products. CNC Rapid Machining Service offers a solution, capable of precisely fabricating parts with complex geometries and precision specifications, which is crucial for design validation, functional testing, or small-batch production. CNC technology can handle various materials, including metals and plastics, ensuring high precision and consistency throughout the production process.

A Solution for Diverse Project Demands

CNC technology offers a flexible solution, capable of meeting the diverse demands of various projects, whether engaged in the design and manufacturing within aerospace, automotive, medical devices, or consumer electronics. CNC Rapid Machining Service adapts to the needs of various industries and projects, providing solutions from single-piece to small batch production, and ensuring precision and consistency at every stage.

In-depth: How Does CNC Rapid Machining Work?

CNC Rapid Machining Service operates by utilizing computer-controlled machine tools, which follow a predefined and programmed set of instructions (G-code) to manipulate material into the desired shape. The process begins with a designer or engineer creating a 3D model using Computer-Aided Design (CAD) software. This model is then converted into a series of executable commands for the CNC machine to follow. The machine, equipped with various tools and attachments, accurately carves, shapes, and constructs the final piece with remarkable precision and speed.

Advantages: Why Choose CNC Rapid Machining Service?

- Precision and Accuracy: CNC machines can produce highly accurate parts, adhering to tight tolerances, ensuring consistency across all produced items.

- Versatility: Capable of handling various materials and complex designs, CNC machining is adaptable to numerous applications and industries.

- Speed: Particularly beneficial for rapid prototyping, CNC machining can quickly turn a design concept into a physical object.

- Scalability: From prototypes to small batch production, CNC machining can scale with your project’s needs, providing consistent quality throughout.

Applications Across Industries

CNC Rapid Machining Service finds applications across a myriad of industries due to its versatility, precision, and scalability. In the aerospace industry, where precision is paramount, CNC machining crafts intricate components that adhere to stringent standards. In the automotive sector, it facilitates the rapid prototyping of parts, enabling quicker design validation and testing. Medical device manufacturers leverage CNC machining to produce specialized surgical tools and devices with exacting specifications. Furthermore, in consumer electronics, CNC machining aids in manufacturing miniature components with complex geometries and tight tolerances.

A Vital Tool in Modern Manufacturing

CNC Rapid Machining Service stands out as an essential tool in the toolkit of modern designers and engineers, offering a robust solution for creating precise, complex, and high-quality parts across various applications and industries. By bridging the gap between digital designs and tangible products, CNC machining not only accelerates the product development cycle but also empowers innovators by providing a versatile manufacturing solution that can adapt to diverse project requirements and complexities.

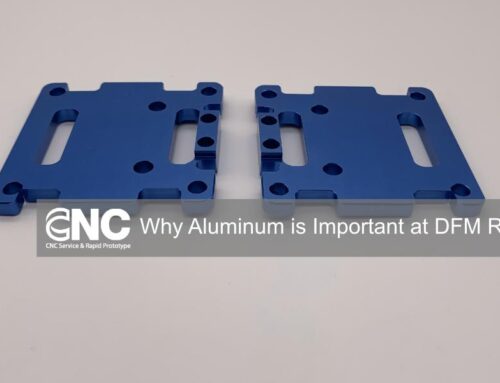

About DFM Rapid

We are a CNC machining China shop in Dongguan. We have 20 CNC milling and turning machines in our shop. We can offer you CNC Rapid Machining Service and low-volume CNC machining services for plastic and metal parts. Also, surface finish like anodized, powder coating is available. If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!