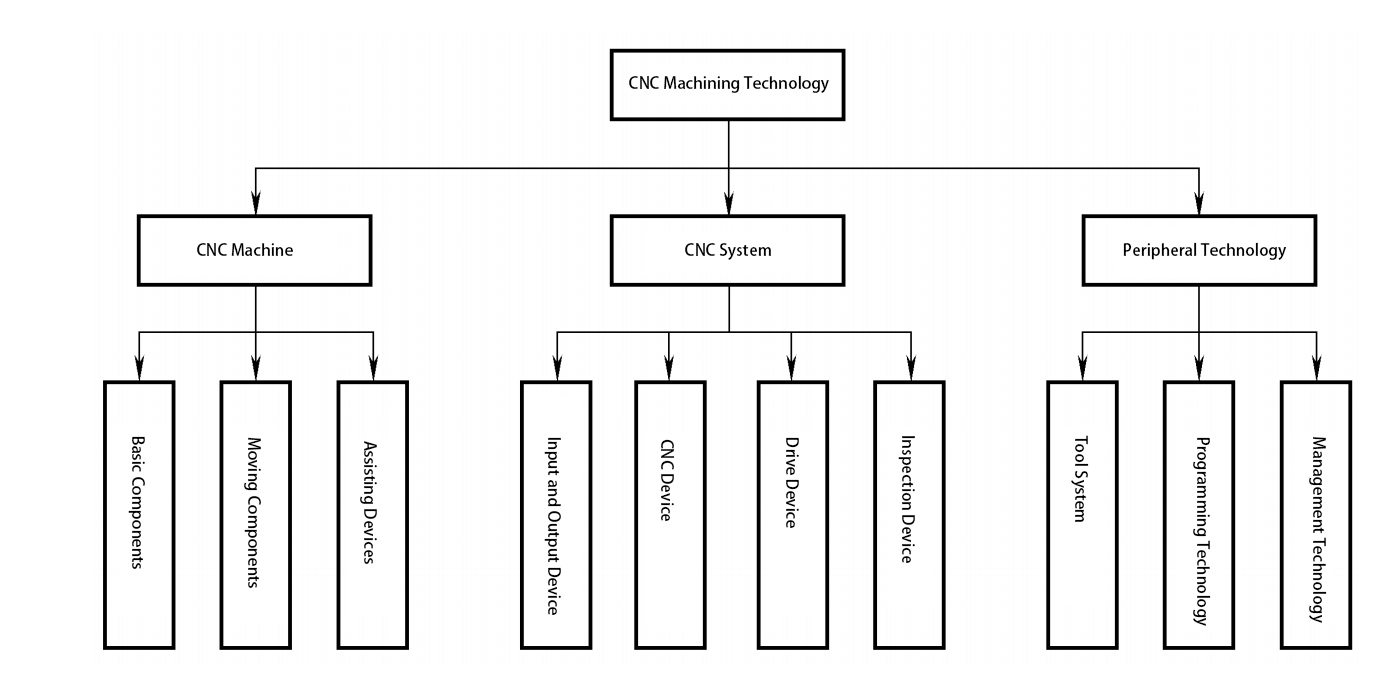

1. Basic concepts of CNC technology

CNC technology, pivotal in modern manufacturing, leverages digital instructions to control one or more mechanical devices. It encompasses the regulation of mechanical aspects such as position, angle, and speed, and manages the flow of mechanical energy. CNC machine tools, embodying this technology, amalgamate manufacturing machinery, computers, automatic control, electric motors, power electronics, sensors, and more, to facilitate automated metal cutting and serve as quintessential mechatronic products.

2. Types of CNC machines

a. CNC lathe

CNC lathes, instrumental in processing various rotary surfaces of parts like shafts, sleeves, and disks, are available in horizontal and vertical configurations. They cater to diverse processing needs, including internal and external cylindrical surfaces, tapered surfaces, shaped rotary surfaces, and threads, among others.

b. CNC Milling Machines and CNC Machining Centers

CNC milling machines, capable of machining complex planes and curved contours, come in various types, including vertical, horizontal, and gantry milling machines. CNC Machining Centers, evolved from CNC milling machines, integrate tool magazines and automatic tool changers, facilitating milling, boring, drilling, tapping, and thread cutting within a single machine tool.

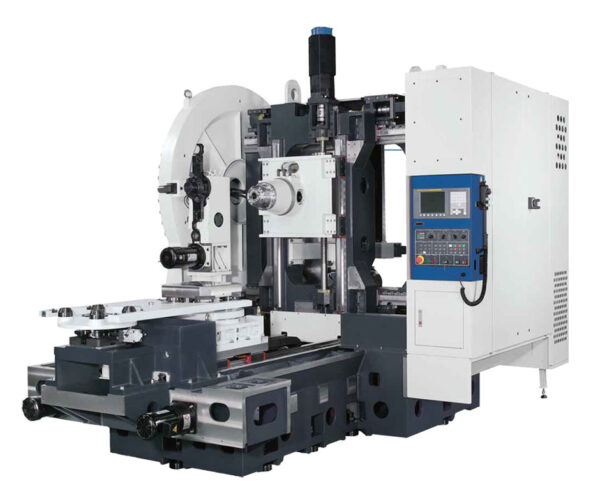

Horizontal CNC milling and boring machine spindle axis parallel to the horizontal, in order to expand the processing range, by increasing the CNC rotary table so that the workpiece can be a clamping to complete the processing of all sides, especially suitable for processing complex boxes, pumps, valves and shells and other parts.

The CNC gantry milling machine is a milling machine with a door frame and a long horizontal bed, which is suitable for milling large parts.

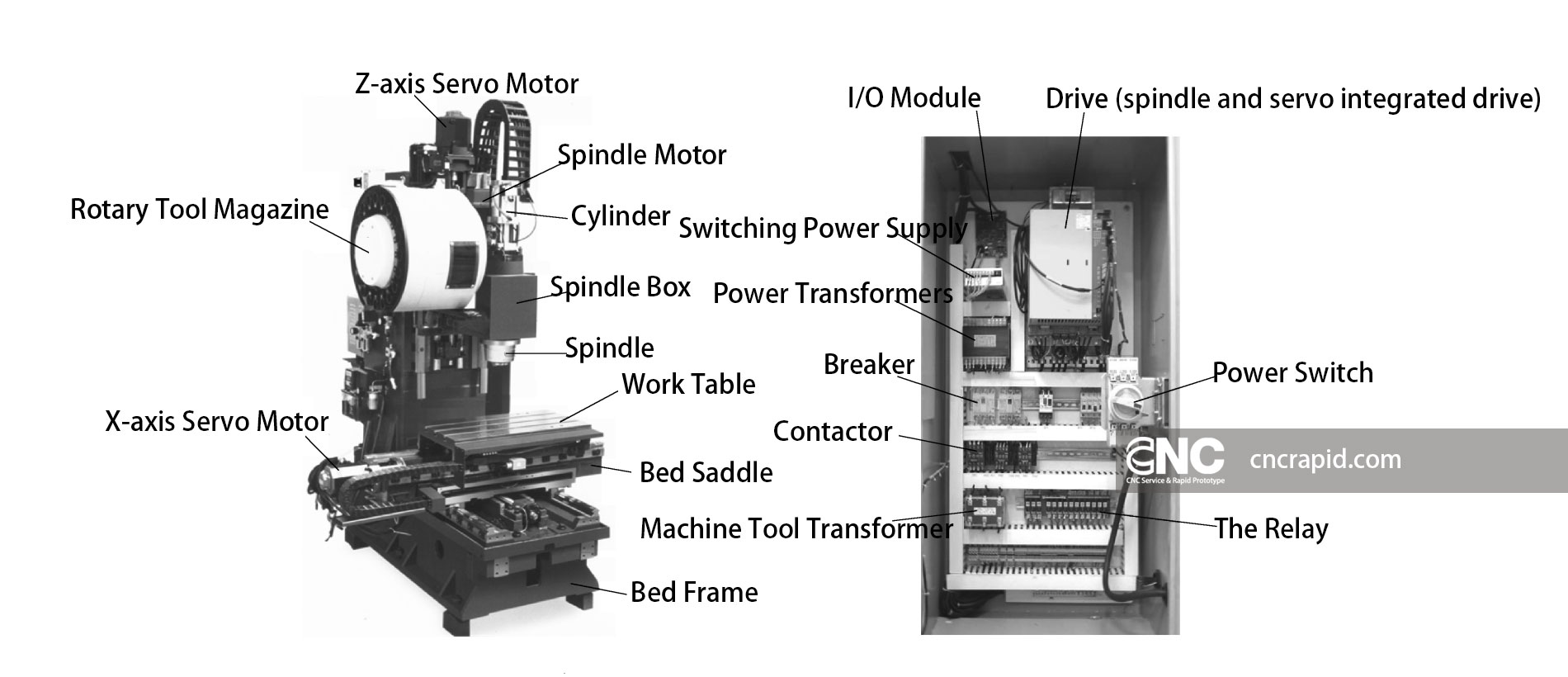

CNC Machining center is developed on the basis of CNC milling machine, with tool magazine and automatic tool changer multifunctional CNC machine tools, which milling, boring, drilling, tapping and thread cutting and other functions in one machine tool. Workpiece in the machining center after a clamping, through automatic tool selection and tool change, in turn to complete multiple processes of processing, greatly improving productivity. CNC Machining centers are vertical machining centers like the picture below.

Horizontal machining centers (like the picture below) and gantry machining centers and other types, equipped with tool magazines are bucket type, disc type and chain type and other forms.

c. CNC Grinder

CNC grinders, utilizing abrasive tools, grind workpiece surfaces. Available as CNC surface grinders, CNC cylindrical grinders, CNC internal grinders, and CNC profile grinders, they cater to various grinding needs.

d. CNC EDM and WEDM

CNC EDM machines utilize electrical discharges between two electrodes of different polarities in an insulating liquid to remove material, excelling in machining complex shapes and difficult materials.

EDM wire cutting process is referred to as “wire cutting”. It uses electrode wire (molybdenum wire, tungsten-molybdenum wire, etc.) as the tool electrode. On the one hand, under the action of the pulse power supply, a spark discharge is formed between the tool electrode and the workpiece, which generates a large amount of heat instantaneously, causing the surface of the workpiece to melt or even vaporize; on the other hand, the electrode wire moves along a predetermined trajectory, thus completing the cutting of the part contour, CNC EDM and WEDM machines are widely used in the field of mold processing.

e. CNC turret punch machines and CNC bending machines

CNC turret punch machines automate the processing of various sheet metal parts, while CNC bending machines facilitate the bending and forming of sheet metal through concave and convex dies.

CNC bending machine is a kind of processing equipment for bending and forming sheet metal by means of concave and convex die.

3. Machining characteristics of CNC machines

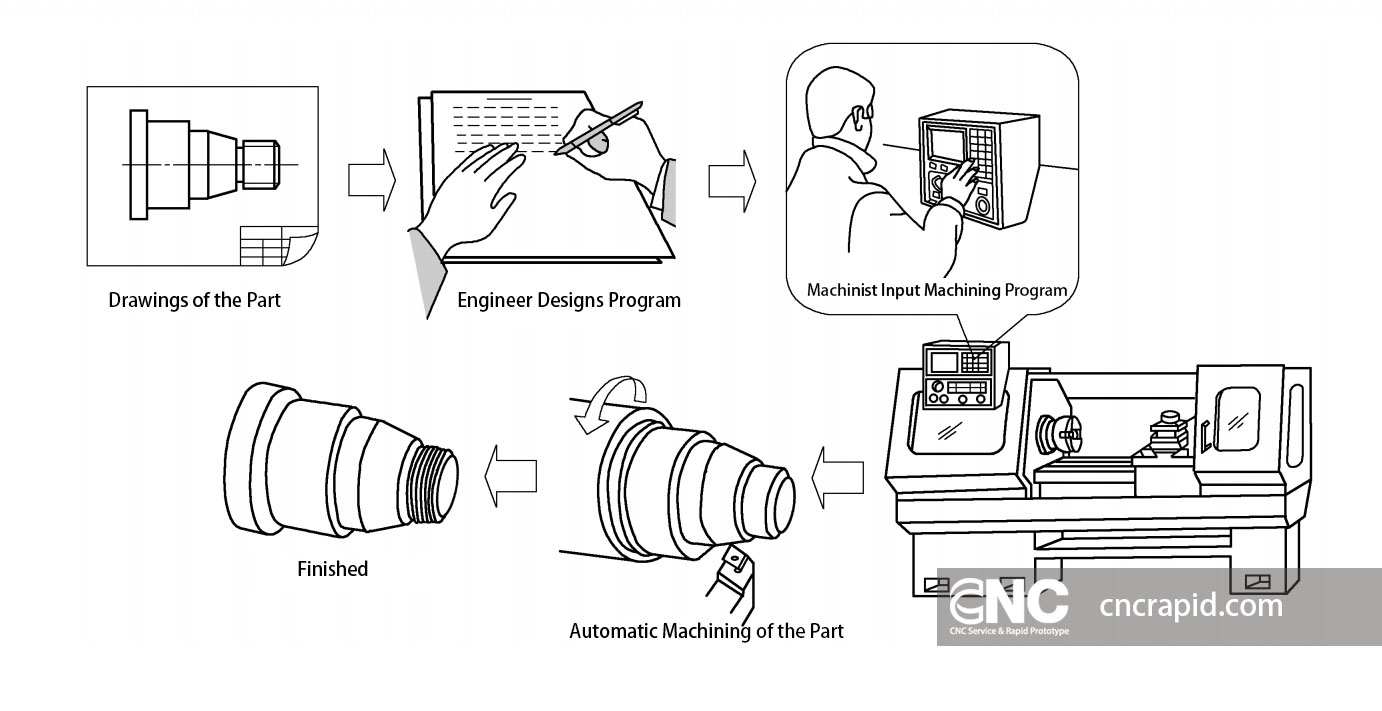

Compared with ordinary machine tools, CNC machine tools process parts automatically according to the machining program, taking CNC lathes as an example, the process of machining parts is shown below.

CNC machines, automating the machining process according to predefined programs, ensure precision and consistency in part machining. They minimize human intervention, ensuring machining accuracy, and maintaining consistency in accuracy. With high automation levels, such as automatic tool change and automatic tooling, CNC machines effectively reduce non-cutting time and enhance machining efficiency.

4. Basic control of CNC machines

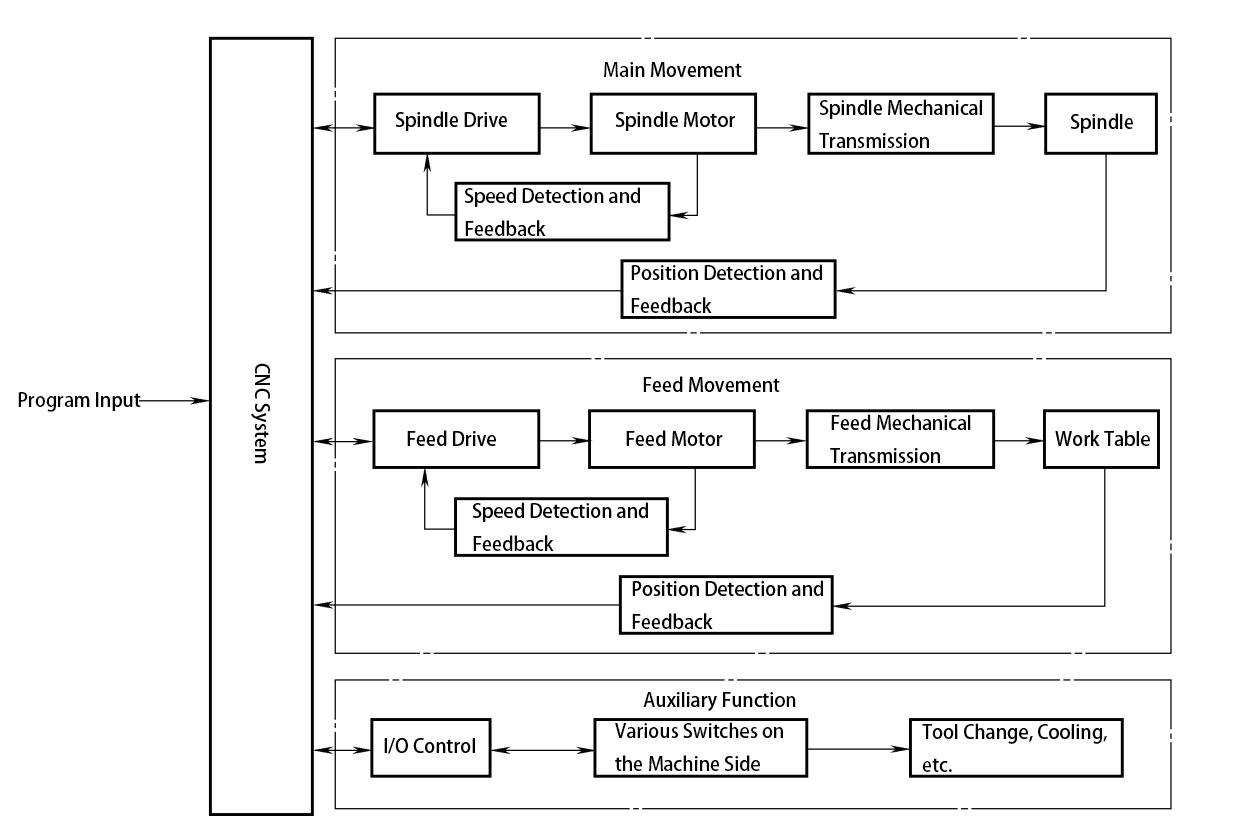

CNC machines, whether they are milling machines, lathes, or any other type, share similarities in their mechanical drive mechanisms, electrical control, and basic CNC commands. They control mechanical movements electrically and include control of main movements, feed movements, and auxiliary functions.

Feed control includes point control and trajectory control (also known as contour control), as shown in below.

5. Trends in CNC technology

a. Speeding Up

High-speed cutting not only enhances productivity but also improves machining quality.

b. High Precision

Advanced CNC machines ensure precision through various means, including error compensation technology and employing high-resolution position detection devices.

c. High Reliability

Reliability in CNC systems is crucial, and measures like fault-tolerant technology and various testing and monitoring techniques are employed to enhance it.

d. Multi-axis Linkage and Functional Compounding

5-axis linkage machining centers and CNC milling machines have become focal points in CNC machining.

e. Application of Industrial Robots in CNC Machining Lines

Integrating CNC machine tools and industrial robots in CNC machining production lines ensures a high degree of automation, short production cycles, and high flexibility.

f. Intellectualize

Intelligent CNC systems enhance work efficiency and ensure a more comfortable and safe working environment.

g. Networking

Networking in CNC systems ensures smooth information flow between various departments in a workshop and enables remote monitoring, control, and management of CNC machine tools.

h. Environmentally Friendly

Greening of machine tools involves using new structures and materials to reduce power losses and employing techniques like dry cutting to reduce pollution emissions.

About DFM Rapid

We are a CNC machining China shop in Dongguan. We have 20 CNC milling and turning machines in our shop. We can offer you CNC rapid prototyping and low-volume CNC machining services for plastic and metal parts. Also, surface finish like anodized, powder coating is available. If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!