Aluminum is a popular choice of material for CNC machining projects due to its many benefits.

The advantages of using aluminum in CNC machining:

- Lightweight: Aluminum is a lightweight material, which makes it an ideal choice for applications where weight is a concern. For example, in the aerospace industry, aluminum is used to create lightweight parts for aircraft and spacecraft.

- High strength-to-weight ratio: Despite its lightweight, aluminum is also a strong and durable material. It has a high strength-to-weight ratio, which means it can withstand high loads and stresses without adding significant weight.

- Corrosion resistance: Aluminum is highly resistant to corrosion, making it an ideal choice for outdoor or marine applications. It can withstand exposure to moisture, saltwater, and other corrosive elements without rusting or corroding.

- Thermal conductivity: Aluminum has excellent thermal conductivity, which means it can transfer heat quickly and efficiently. This makes it a popular choice for applications where heat dissipation is important, such as in electronics or automotive components.

- Machinability: Aluminum is a highly machinable material, which means it can be easily shaped, cut, and drilled using CNC machining techniques. This makes it a cost-effective and versatile material for creating complex parts and components.

The benefits of aluminum make it a popular choice of material for CNC machining projects across a range of industries. If you are looking for a lightweight, durable, and highly machinable material, aluminum may be the ideal choice for your project.

|

|

Aluminum vs. Other Materials:

| Material | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, high strength-to-weight ratio, corrosion-resistant, excellent thermal conductivity, easy to machine, good surface finish | Not as strong as steel or brass, not suitable for high-temperature applications, may not be suitable for high-stress applications |

| Brass | Corrosion-resistant, high strength, excellent thermal conductivity, easy to machine, attractive appearance | Can be expensive compared to other materials, heavier than aluminum, not as strong as steel, may require additional surface finishing |

| Stainless Steel | High strength, stiffness, and toughness, excellent corrosion resistance, suitable for high-temperature and high-stress applications | Heavier than aluminum or plastic, can be more difficult to machine, may require additional surface finishing, can be more expensive |

| Steel | High strength, stiffness, and toughness, excellent wear resistance, suitable for high-temperature and high-stress applications | Heavier than aluminum, can be more difficult to machine, may require additional surface finishing, corrosion resistance can be an issue |

| Plastic | Low cost, lightweight, good chemical resistance, can be easily molded into complex shapes, suitable for low-stress applications | Lower strength than metal materials, not suitable for high-temperature or high-stress applications, can be prone to deformation or warping during machining |

Tips on how to optimize designs for aluminum CNC machining:

- Wall thickness: It is important to maintain consistent wall thickness throughout the part to avoid warping or distortion during the machining process. This is especially important for larger parts or those with thin walls. As a rule of thumb, try to maintain a wall thickness of at least 1mm.

- Hole sizes: When designing holes in aluminum parts, it is important to consider the diameter and depth of the hole, as well as its location relative to other features of the part. For example, larger holes may require additional support structures or reinforcement to prevent deformation during the machining process.

- Fillet radii: When designing corners or edges in aluminum parts, consider using fillet radii to reduce stress concentrations and improve the part’s overall strength. A fillet radius of at least 0.5mm is recommended.

- Avoid sharp angles: Avoid sharp angles or corners in aluminum parts, as they can be difficult to machine and may cause stress concentrations or distortion. Instead, use curves or fillets to create smooth transitions between features.

- Material selection: Choose the right grade of aluminum for your application to ensure optimal performance and machining results. For example, 6061-T6 is a popular choice for CNC machining due to its high strength and machinability.

- Workholding: Choose the right workholding method to ensure the part remains securely in place during the machining process. This can include using vices, clamps, or custom fixtures designed specifically for your part.

Common Applications of aluminum CNC machining projects

- Automotive parts: Aluminum is also commonly used in the automotive industry, particularly for engine components such as cylinder heads, blocks, and pistons. CNC machining is used to produce high-precision parts with tight tolerances and complex geometries.

- Medical equipment: Aluminum is used in the production of medical equipment due to its high strength and corrosion resistance. CNC machining is used to produce medical components such as surgical instruments, implantable devices, and diagnostic equipment.

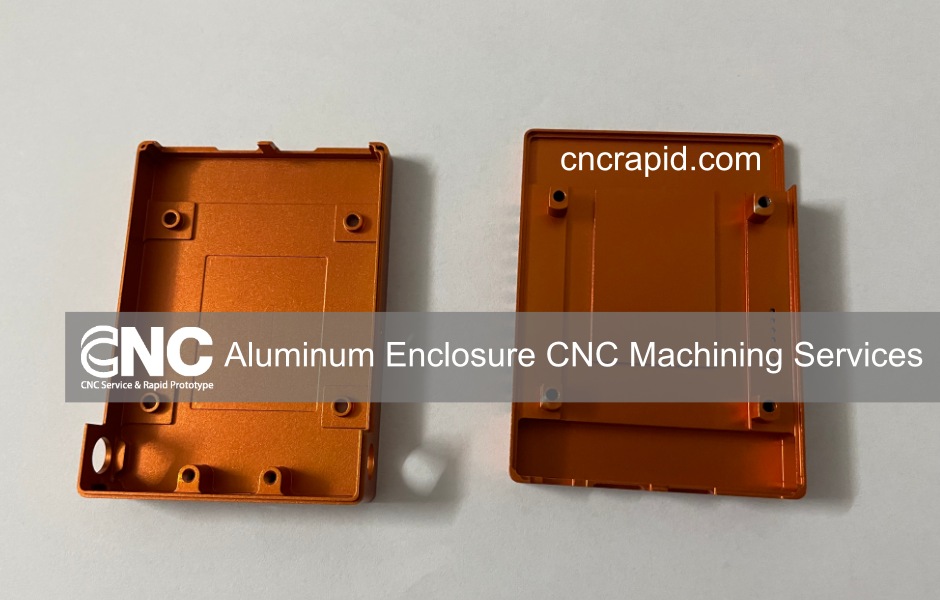

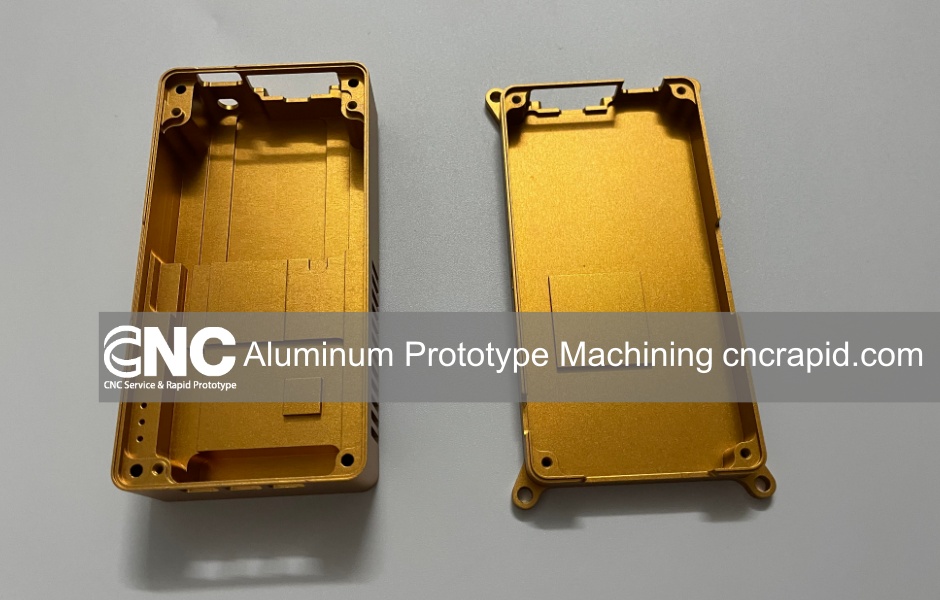

- Electronics enclosures: Aluminum is a popular material for electronic enclosures due to its electromagnetic shielding properties and ability to dissipate heat. CNC machining is used to produce enclosures with complex shapes and precise tolerances.

|

|

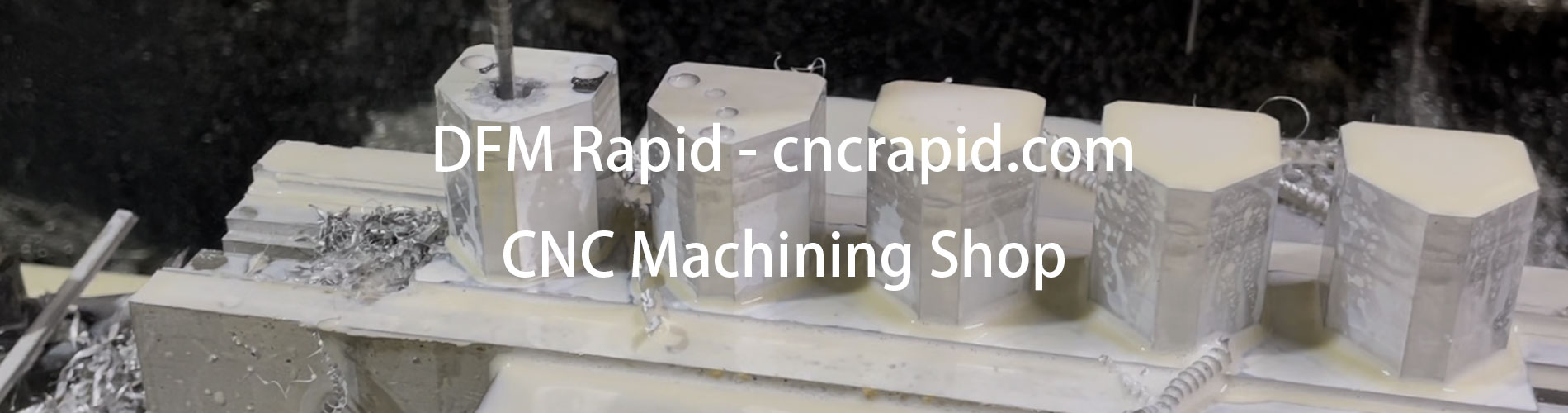

Why Choose DFM Rapid?

We specialize in Aluminum CNC Machining, providing you with high-quality parts and exceptional service.

|

|

At our CNC shop, we use advanced CNC machines and the latest technology to produce precision aluminum parts to your exact specifications. Our experienced team of machinists is skilled in the art of CNC machining and has a wealth of experience working with aluminum.

We understand that your project is unique and requires personalized solutions. That’s why we work closely with you to ensure that we meet all of your specific requirements. Our team is committed to delivering the highest level of quality, and we ensure that each part undergoes multiple inspections before it leaves our shop.

Whether you need a one-off prototype or high-volume production, we have the expertise and capabilities to deliver precision aluminum parts on time and on budget. Trust us with your Aluminum CNC Machining needs, and we’ll ensure that you receive the highest level of service and quality. Contact us today to learn more.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!