CNC machining is a manufacturing process that offers precision, accuracy, and consistency. However, to get the most out of CNC machining, you need to optimize your design for the process.

Tips for optimizing your design for CNC machining

- Material Selection:

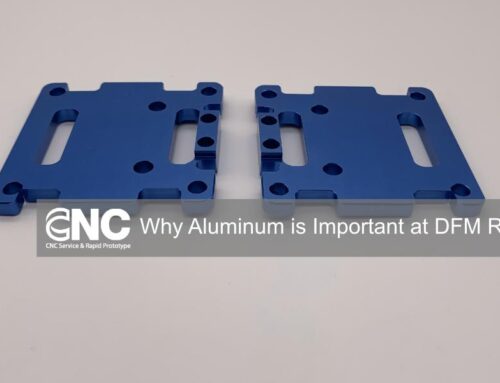

The material you choose for your part can affect its machinability. Materials like aluminum and brass are easy to machine, while harder materials like titanium and Inconel are more challenging. When choosing a material for your part, consider the material’s properties, machinability, and cost. - Part Geometry:

The geometry of your part can also affect its machinability. Parts with complex shapes or sharp corners can be challenging to machine. Use fillets or radii to help improve the tool’s path and prevent tool breakage. Simplify the geometry of your part as much as possible to reduce machining time and cost. - Tolerance Requirements:

The tolerances needed for your part can affect the machining process. Tighter tolerances may require more expensive equipment or additional machining operations. Determine the tolerances needed for your design and ensure that they are achievable with CNC machining. - Surface Finish:

The surface finish of your part can affect its performance and appearance. Choose a surface finish that is appropriate for the intended use of the part. Smoother finishes may require additional machining operations, while rougher finishes may not be suitable for certain applications. - Tool Path Optimization:

Optimizing the tool path can help reduce cycle time and minimize tool wear. Use the appropriate tool for each operation and optimize the cutting parameters for the material being machined. Avoid features that require multiple setups or excessive tool changes. - Design for Manufacturing:

Consider the manufacturing process when designing your part. Simplify the part and reduce the number of operations to save time and money. Avoid features that require multiple setups or excessive tool changes. - Test Your Design:

Create a prototype and test it to ensure that it meets your design requirements. Make any necessary adjustments to optimize the design for CNC machining.

By following these tips, you can optimize your design for CNC machining and reduce the time and cost of manufacturing your parts. CNC machining offers precision, accuracy, and consistency, but to get the most out of it, you need to optimize your design for the process.

Optimizing your design for CNC machining can help reduce machining time and cost, and ensure that your parts meet your design requirements. At DFM Rapid, we have years of experience in CNC machining and can help you optimize your design for the process. Whether you need help with material selection, part geometry, tolerance requirements, or tool path optimization, our team of experts can guide you through the process and deliver high-quality parts on time and on budget. Contact us today to learn more about how we can help with your CNC machining projects.

Contact DFM Rapid

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!