When it comes to manufacturing, precision and efficiency are key. That’s why more and more companies are turning to customized CNC parts to improve their processes and products.

|

|

Benefits of Customized CNC Parts:

Customized CNC parts offer several advantages over standard parts. For one, they can be designed to exact specifications, which means they’ll fit perfectly in your manufacturing process. They can also be optimized for performance and durability, which can lead to better products and lower maintenance costs. Finally, customized CNC parts can often be produced more quickly and cost-effectively than traditional manufacturing methods.

Types of Customized CNC Parts:

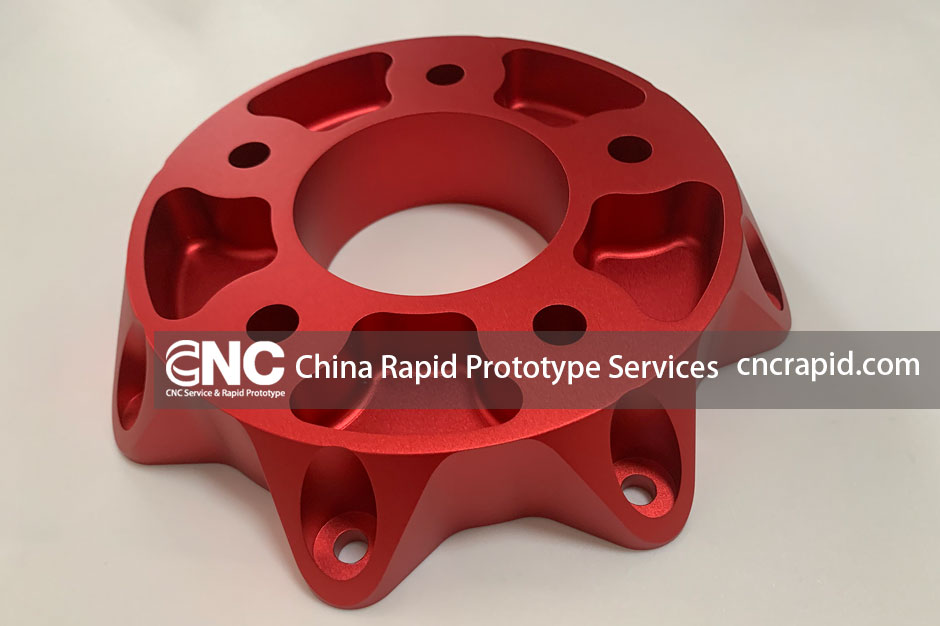

CNC machining is a versatile technology that can produce a wide range of parts and components used in various industries. Its precision and efficiency make it an essential tool in modern manufacturing.

|

|

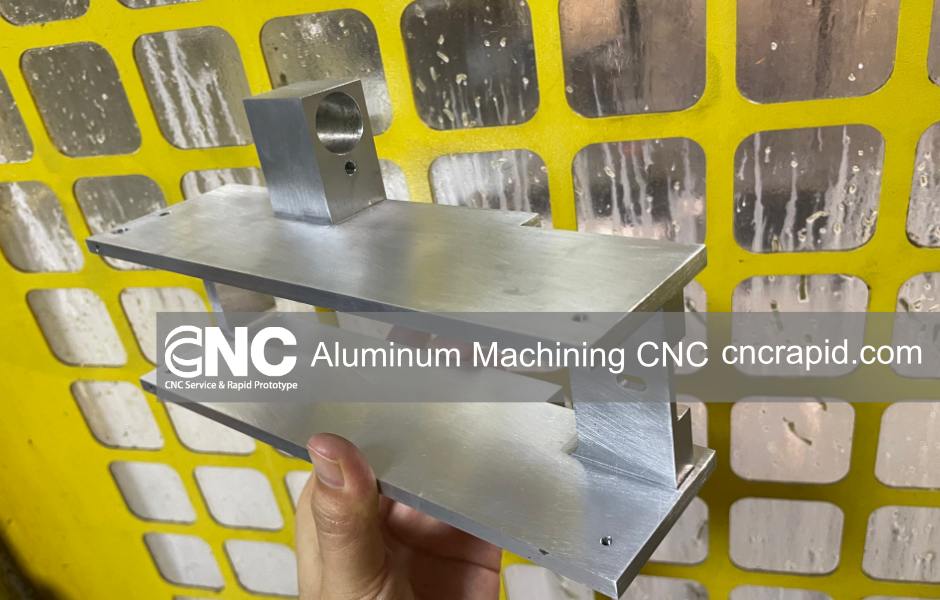

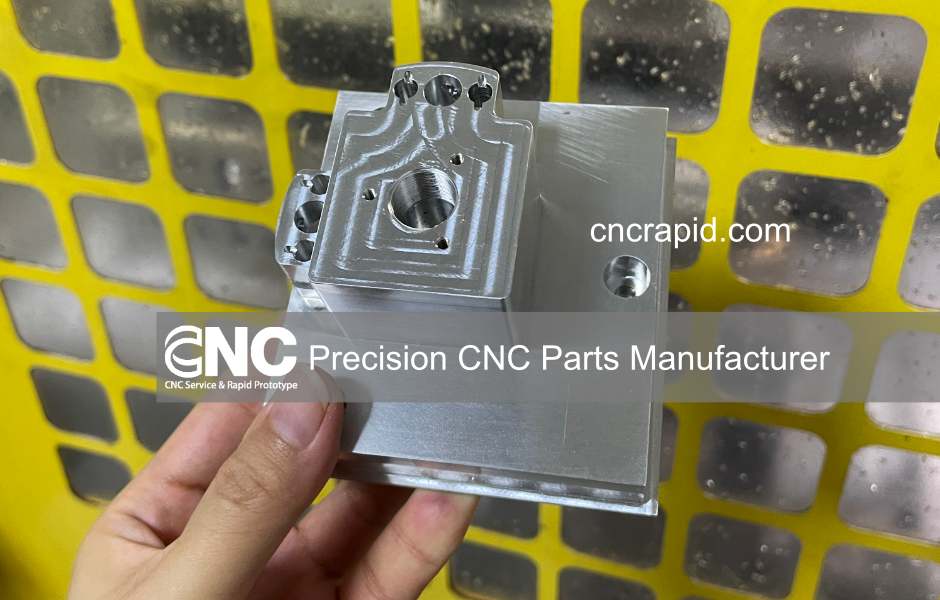

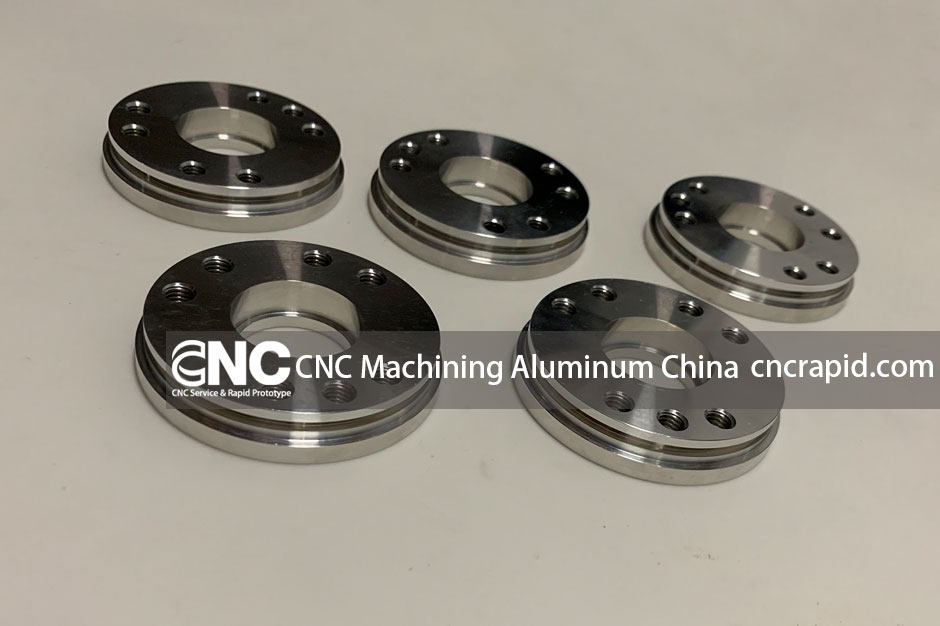

There are many different types of customized CNC parts, depending on your manufacturing needs. Some examples include specialized tools, precision components, and complex geometries. These parts can be made from a variety of materials, including metals, plastics, and composites.

- Engine components: CNC machines can produce engine components, such as cylinder heads, connecting rods, crankshafts, and camshafts.

- Aerospace components: CNC machining is commonly used to produce aerospace components, including turbine blades, engine mounts, and brackets.

- Medical components: CNC machining can produce medical components, such as orthopedic implants, surgical instruments, and medical devices.

- Automotive components: CNC machining can produce automotive components, such as transmission cases, suspension components, and brake components.

- Electronic components: CNC machines can produce electronic components, such as heat sinks, enclosures, and brackets.

- Industrial components: CNC machines can produce a range of industrial components, such as valves, pumps, gears, and bearings.

- Prototyping: CNC machines can produce prototypes of new parts and components, enabling manufacturers to test and refine their designs before moving to full production.

|

|

Designing Customized CNC Parts:

Designing customized CNC parts requires a thorough understanding of the manufacturing process and the specific needs of your business. This typically involves CAD modeling and CAM programming, which allows you to create a 3D model of the part and simulate the manufacturing process before production begins. This ensures that the part will fit seamlessly into your existing process and that any potential issues are addressed before production starts.

Materials:

The choice of materials for CNC parts depends on the specific application and requirements of your product. For example, some parts may need to withstand high temperatures or corrosive environments, while others may need to be lightweight and durable. By selecting the right material, you can ensure that your part performs optimally and meets your product specifications.

Quality Control:

Quality control is an essential part of the CNC machining process. This includes inspection, testing, and certification, to ensure that the part meets all relevant standards and specifications. By investing in quality control, you can ensure that your parts are consistent, reliable, and perform at the highest level.

If you’re in need of customized CNC parts, DFM Rapid is your best choice. Our experienced team and advanced CNC machines allow us to produce high-quality, precision parts to your exact specifications. Whether you need a prototype or a full production run, we’re here to help bring your project to life. Contact us today to learn more about our CNC machining services and how we can help you with your next project.

|

|

Who Are We?

At DFM Rapid, we specialize in providing high-quality precision machining services to customers in a variety of industries. We have a team of skilled professionals and advanced cnc machines that can handle even the most complex machining projects. Whether you need custom parts for your manufacturing process or prototypes for a new product, we’re here to help you achieve your goals.

Our Services:

At our CNC shop, we offer a range of services to meet your specific needs. Some of our key services include:

- CNC milling: Our milling machines can produce parts with high accuracy and repeatability, using various materials such as aluminum, stainless steel, brass, and plastics.

- CNC turning: Our lathes can create precision components with tight tolerances, in a range of sizes and shapes.

- Prototype machining: We can help you develop and refine your product designs, with quick turnaround times and expert guidance.

- Custom machining: Our team can work with you to design and produce custom parts that meet your exact specifications, ensuring they fit seamlessly into your manufacturing process.

|

|

Why Choose DFM Rapid?

At DFM Rapid, we’re committed to providing exceptional customer service and high-quality workmanship. Here are just a few reasons why you should choose us:

- Experienced professionals: Our team has years of experience in CNC machining and is dedicated to staying up-to-date with the latest technology and techniques.

- Advanced equipment: We use advanced equipment and software to ensure that our parts are produced with high accuracy and efficiency.

- Quick turnaround times: We understand that time is of the essence, which is why we prioritize quick turnaround times without compromising on quality.

- Competitive pricing: We offer competitive pricing without sacrificing quality, so you can get the parts you need at a reasonable cost.

At DFM Rapid, we’re passionate about providing high-quality CNC machining services that help our customers succeed. Whether you’re looking for a one-off prototype or ongoing production runs, we’re here to help you achieve your goals. Contact us today to learn more about how we can assist with your precision machining needs.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!