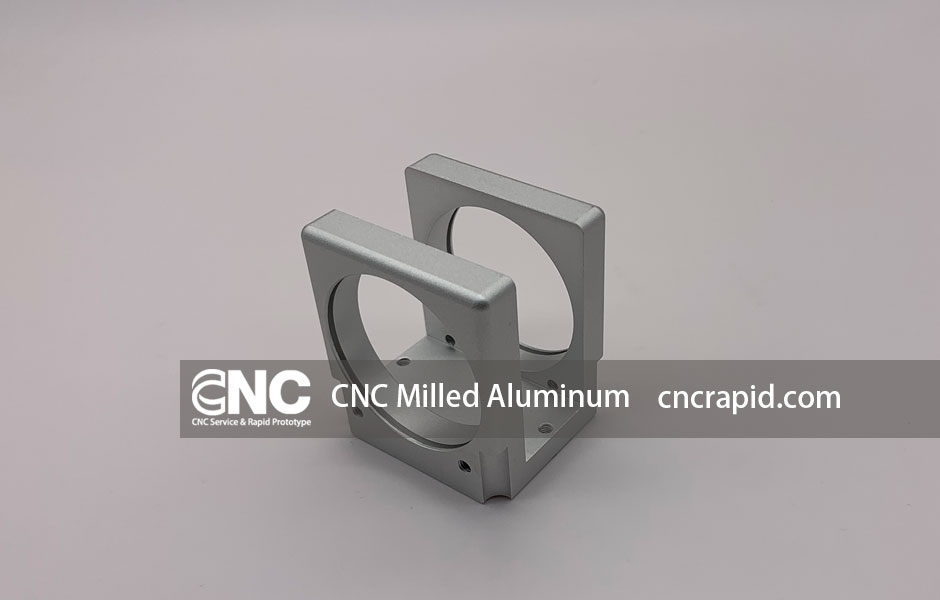

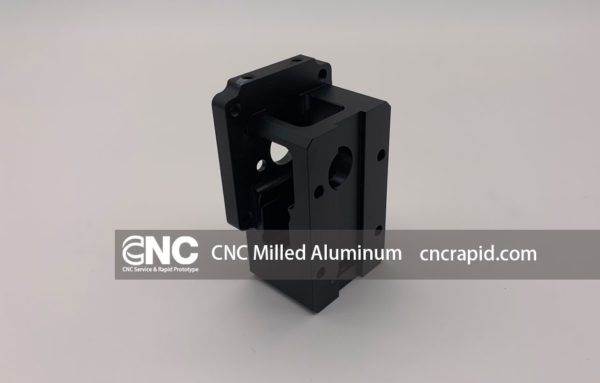

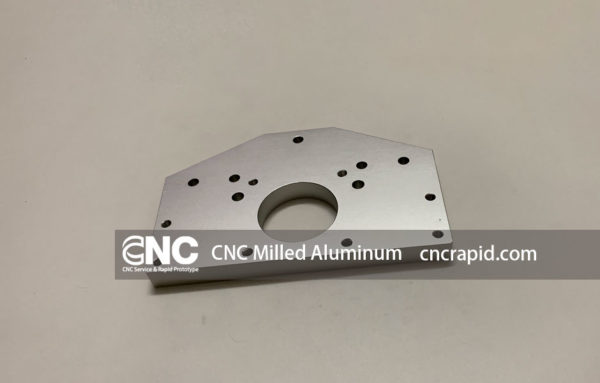

CNC Milled Aluminum. CNC milled aluminum is a process of creating parts from aluminum blocks or sheets using a computer-controlled milling machine. The milling machine rotates a cutting tool or a workpiece to remove material and create a desired shape.

CNC milled aluminum can produce complex and precise parts for various applications, such as vehicles, aircraft, and medical devices. CNC milled aluminum has advantages such as high speed, low cost, and wide material range. Custom Machining part generally refers to piece-parts, or component parts which are custom machined to a customer’s specific requirements.

Advantages of CNC machining aluminum

- Easy machinability: Aluminum is soft, ductile, and chips easily, which makes it suitable for various CNC machining processes. It also requires less power and tooling than steel.

- High strength-to-weight ratio: Aluminum is light but strong, which makes it ideal for parts that need to withstand high stress or reduce weight. Aluminum is widely used in aerospace and automotive industries for this reason.

- Corrosion resistance: Aluminum is resistant to common atmospheric and marine conditions, and can be further enhanced by anodizing. This makes it durable and suitable for outdoor applications.

- Electrical conductivity: Aluminum has high electrical conductivity compared to other metals, which makes it useful for electrical components. It can also be easily combined with other materials to form alloys with different properties.

- Low temperature performance: Aluminum retains its softness, ductility, and strength at very low temperatures, which makes it suitable for applications that require cold resistance.

Custom machined parts are made on different types of precision equipment, depending on their shape and specifications. A custom machined part may go through several operations before it is finished. Custom machined parts usually cost more than mass-produced parts, but they have some advantages. They are more precise, stronger and/or more reliable, and faster to make than most other methods.

DFM Rapid is your rapid prototype machine shop with instant quotes. Our CNC machines can handle small radius cuts and maintain a high-quality level whether you want one piece or one hundred. Chamfered edges, multi-radius curves, and tapped holes are a few things that make machining a part more workable for any projects. We take pride in making quality, custom, low cost, machined parts.

CNC Milled Aluminum

CNC machining is ideal for making high-quality rapid prototypes from plastic or metal without investing in expensive tooling. Your parts will achieve tighter tolerances with better surface finishes than with other prototyping methods. We can also machine all the features needed for a fully functional part, including tapped and threaded holes and precisely flat surfaces.

Get in Touch

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!