The demand for high-quality, accurate, and cost-effective components has skyrocketed in recent years, with industries such as automotive, aerospace, medical, and consumer electronics continually seeking reliable manufacturing partners. DFM Rapid’s CNC precision machining parts have emerged as a leading solution for these industries, offering unparalleled quality, efficiency, and customization.

CNC precision machining is a process that employs computer-controlled machines to create parts with extremely tight tolerances and intricate details.

Advantages of CNC Precision Machining

- High precision and accuracy: CNC precision machining ensures the production of parts with remarkable precision and accuracy, making it ideal for industries that require components with strict specifications and tolerances.

- Consistency: CNC machines can produce large quantities of identical parts without deviations in quality, ensuring consistent results across an entire production run.

- Flexibility: CNC precision machining allows for the production of complex parts with intricate geometries that would be difficult or impossible to achieve using conventional manufacturing methods.

- Reduced labor costs: The automated nature of CNC precision machining reduces the need for manual intervention, leading to lower labor costs and increased efficiency.

- Customization: CNC machines can be easily programmed to create custom parts according to the specific requirements of a given project, enabling manufacturers to cater to a wide range of applications and industries.

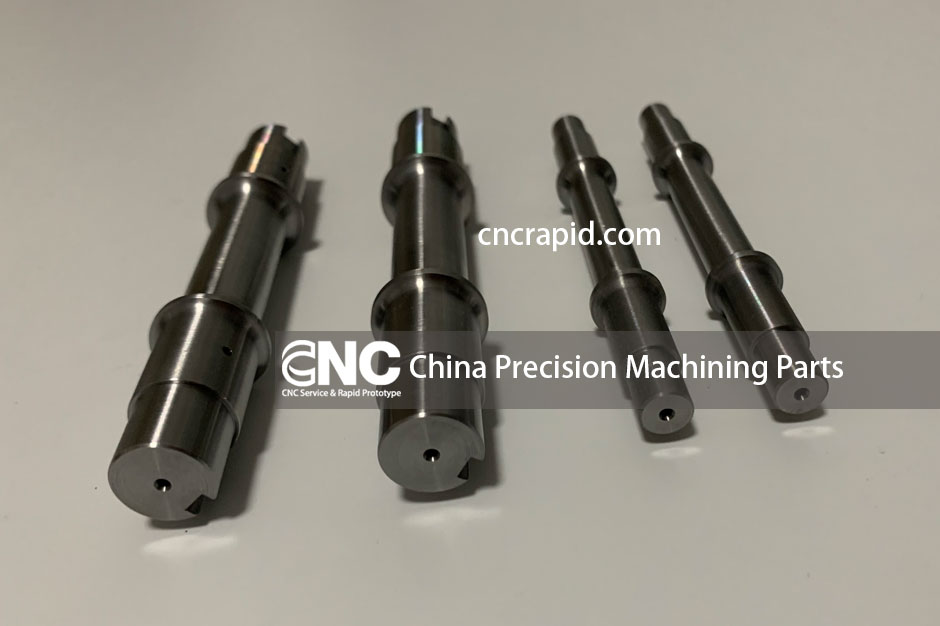

China precision machining parts. CNC precision machining has transformed the manufacturing landscape by providing a highly accurate, efficient, and flexible solution for producing complex components across various industries. As technology continues to advance and industries place greater emphasis on precision and efficiency, CNC precision machining will undoubtedly play an increasingly significant role in shaping the future of manufacturing.

.

We use advanced equipment to offer you a variety of CNC machining services including milling, turning, EDM, wire EDM, surface grinding and much more. Our skilled machinists can make turned and milled parts using a wide range of plastic and metal materials.

CNC machining is a practical option for everything from prototype manufacturing to production runs. We are a one-stop shop for custom machining and manufacturing.

What is CNC Machining?

CNC Machining is also called computer numerical control machining, it is digital manufacturing technology. It is one of the most accurate manufacturing methods known by engineers all over the world.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

Contact us

If you need Metal & Plastic parts machined for rapid prototypes or production, please feel free to get a quote online

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!