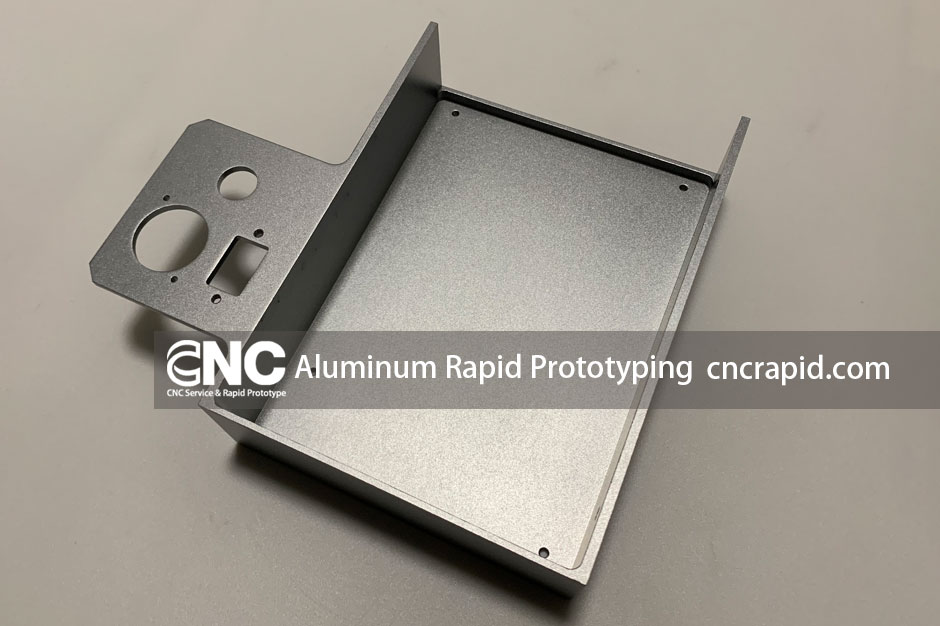

Rapid prototyping is a crucial step in the product development process, enabling manufacturers to quickly create functional prototypes to test their designs before moving on to production. One of the most cost-effective solutions for rapid prototyping is aluminum with CNC technology.

|

|

Aluminum rapid prototyping with CNC technology is a highly cost-effective solution for manufacturers who need to create functional prototypes quickly and efficiently. Here are some of the reasons why:

- Material cost savings: Aluminum is a highly versatile and cost-effective material for rapid prototyping. It is strong, lightweight, and easy to machine and form, making it an ideal choice for creating complex parts with tight tolerances. By using aluminum instead of other more expensive materials, manufacturers can significantly reduce their material costs.

- Reduced labor costs: CNC technology allows for highly accurate and efficient machining, reducing the need for manual labor. This means that manufacturers can produce parts more quickly and with fewer errors, resulting in a more cost-effective process.

- Faster product development cycle: Rapid prototyping with CNC technology allows for faster product development cycles, as manufacturers can quickly create and test functional prototypes. This can help to identify potential issues early on, saving significant time and money in the long run.

- Greater accuracy and consistency: CNC technology allows for highly precise and consistent parts, reducing the need for costly rework or redesign. This not only saves time and money, but it also results in higher quality products.

- Reduced waste: Aluminum rapid prototyping with CNC technology produces less waste than traditional manual processes. This means that manufacturers can save on material costs and reduce their environmental impact.

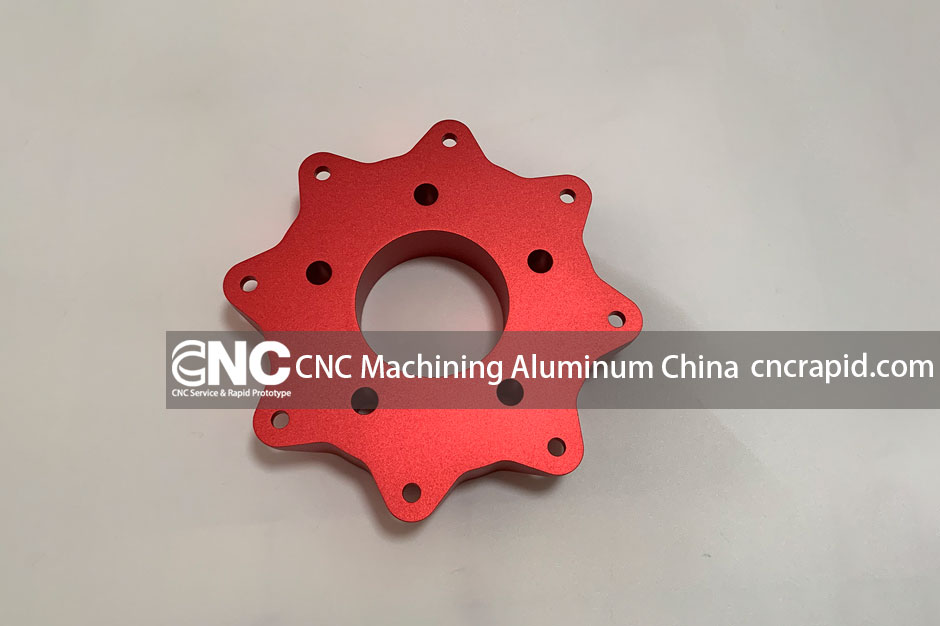

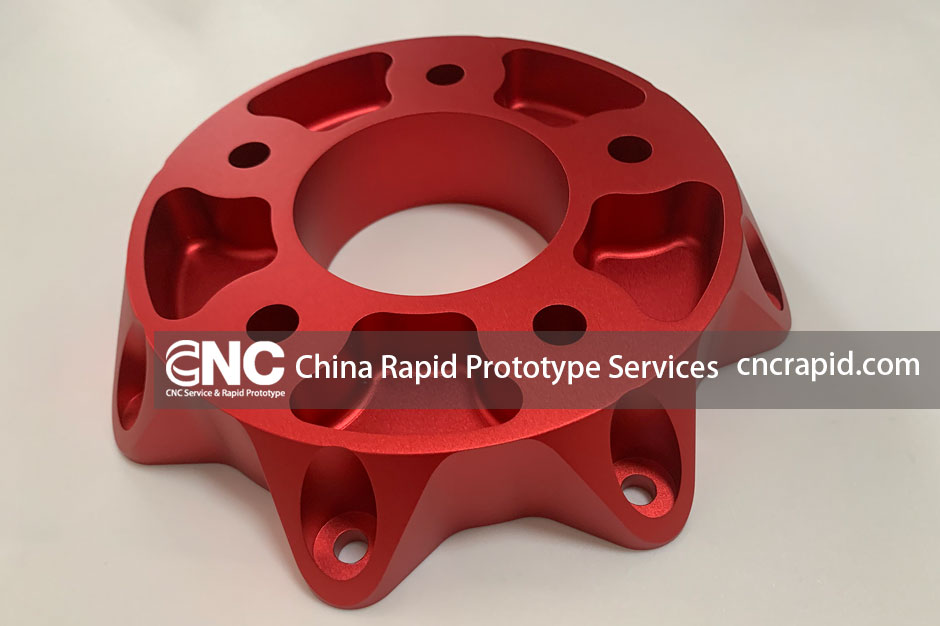

Also, aluminum rapid prototyping with CNC technology is highly versatile and can be used in a variety of industries, including aerospace, automotive, and medical. By using this cost-effective solution, manufacturers can quickly and efficiently produce functional prototypes that meet their exact specifications, while also enjoying significant cost savings.

|

|

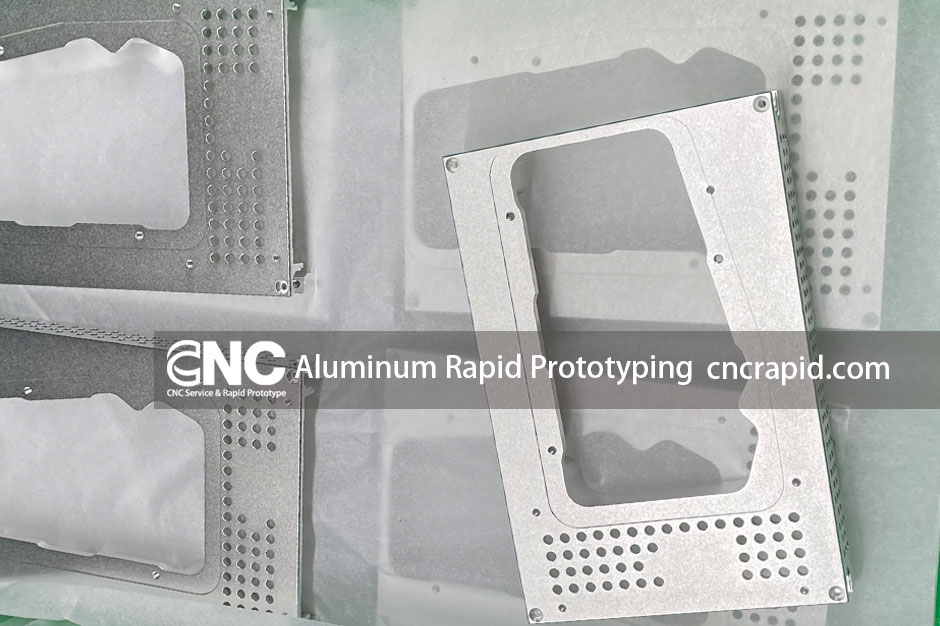

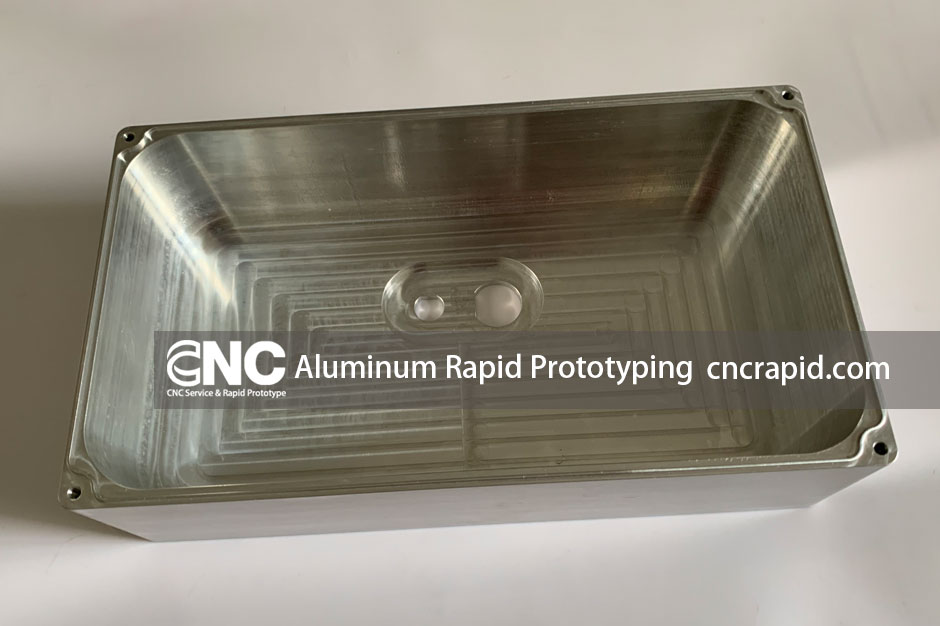

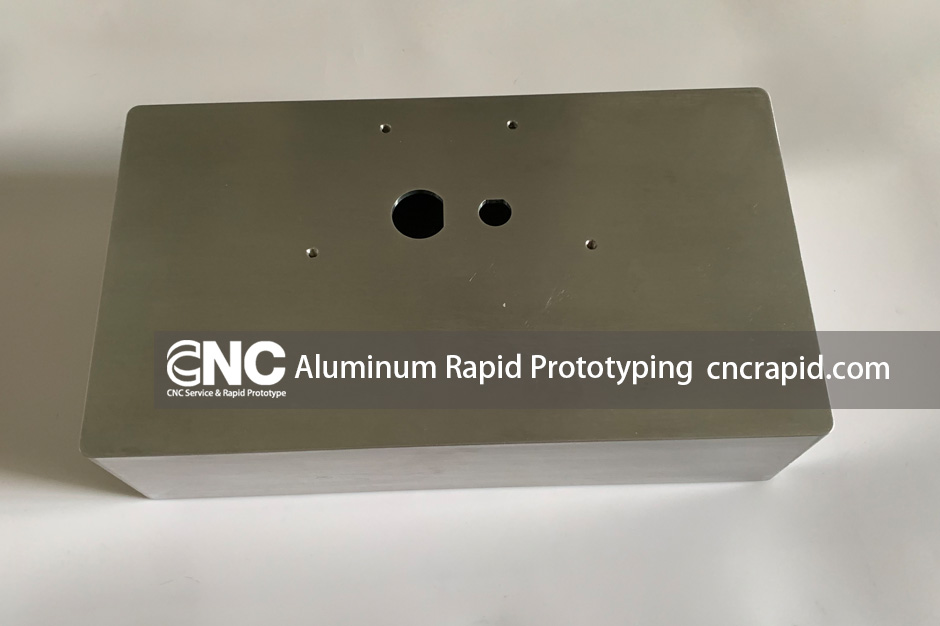

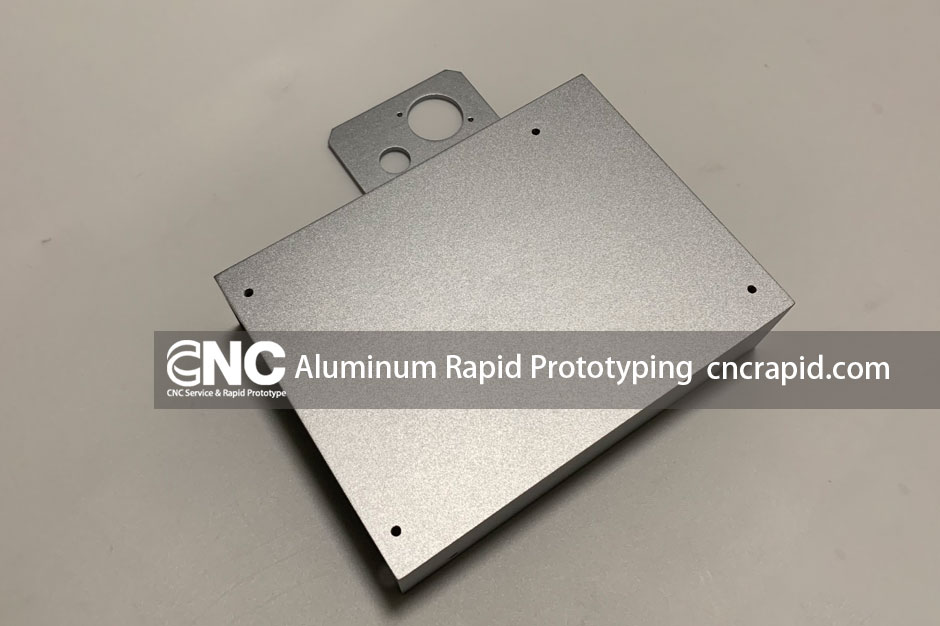

Aluminum is an ideal material for rapid prototyping with CNC technology, offering numerous benefits that make it a popular choice for manufacturers. Here are some of the key advantages of using aluminum for rapid prototyping with CNC technology:

- Strength and durability: Aluminum is a strong and durable material, with excellent resistance to corrosion and fatigue. This makes it an ideal choice for producing parts that need to withstand demanding conditions, such as those used in aerospace, automotive, and medical applications.

- Lightweight: Aluminum is a lightweight material, which can be an important consideration for manufacturers looking to produce products that need to be portable or have weight limitations. By using aluminum, manufacturers can reduce the weight of their products without sacrificing strength or durability.

- Machinability: Aluminum is a highly machinable material, which means that it is easy to work with using CNC technology. This makes it a popular choice for rapid prototyping, as it allows manufacturers to quickly produce accurate and complex parts with tight tolerances.

- Cost-effective: Aluminum is a cost-effective material for rapid prototyping with CNC technology, as it is readily available and relatively inexpensive compared to other materials. This means that manufacturers can produce parts quickly and at a lower cost, making it an attractive option for both small and large production runs.

- Customizability: Aluminum is highly customizable, making it an ideal material for producing prototypes that meet specific design requirements. By using CNC technology, manufacturers can quickly and easily produce highly customized parts, including those with intricate designs or features.

|

|

Why Choose DFM Rapid?

If you’re looking for a reliable and cost-effective solution for your aluminum rapid prototyping needs, our CNC shop is here to help. Our advanced equipment and experienced technicians allow us to produce high-quality prototypes that meet your exact specifications, no matter how complex your project may be.

At our CNC shop, we are committed to providing our clients with exceptional service and support throughout the prototyping process. From initial concept to final product, we work closely with you to ensure that your prototype is an accurate representation of your final product.

|

|

Contact us today to learn more about how we can help take your product development to the next level. We look forward to working with you!

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!