CNC Machining, standing for Computer Numerical Control Machining, is a widely utilized digital manufacturing technology. This method is employed to manufacture parts that demand tight tolerances and intricate complexity. Being a subtractive manufacturing technology, CNC machining creates parts by removing material from a solid block, referred to as the blank or workpiece, through a variety of automated cutting operations.

How Does the CNC Machining Process Work?

Navigating through the CNC machining process involves several crucial steps, each contributing to the efficient production of high-quality parts.

1. Analyzing the Part Pattern

Ensure a comprehensive analysis of the part’s geometric shape, size, and technical requirements. Confirm the completeness of drawing sizes and the accuracy of technical requirements. Establish an appropriate programming origin and convert the part drawing’s dimension as needed to align with CNC machining characteristics.

2. Determining the CNC Plan and Machine Selection

Identify the parts of the workpiece that require CNC machining and decide on the machining method. Considerations should include the type of CNC machine, the power of the main motion motor, the processing range of the feed movement, and the appropriate CNC system and its programming methods.

3. Establishing the Processing Procedure

This involves selecting a positioning datum and dividing processes and steps. Adopt the principle of process concentration in CNC machining, arranging most similar surfaces in one process, while observing the principle of separating roughing and finishing.

4. Clamping Plan and Fixture Selection

Ensure the workpiece is positioned accurately and clamped reliably during machining. Consider the convenience of the tool setting of the workpiece coordinate system and opt for general-purpose fixtures when possible.

5. Cutting Tool Selection

Opt for machine-clamped indexable tools for CNC machining, considering the tool’s structural characteristics. For example, choose a flat-bottom end mill for rough machining and consider a rounded end mill for semi-finishing.

6. Determining Start and End Points for Tool Setting and Cutting

The tool setting point, which is the starting point of the tool’s movement relative to the workpiece, should have a suitable and definite offset relative to the workpiece origin. Ensure a smooth transition point between rapid movement and cutting interpolation movement.

7. Opting for the Right Toolpath

Prioritize main issues like the shortest cutting time and the best machined surface quality when dealing with toolpaths. Also, consider whether tool radius compensation and tool length compensation are used during machining.

8. Determining a Reasonable Cutting Amount

In addition to referring to the parameter selection of ordinary machine tool cutting, consider that CNC machine tools generally have adjustable spindle speed and feed rate characteristics. Control the override switch of the spindle speed and the feed speed to determine the actual machining cutting amount.

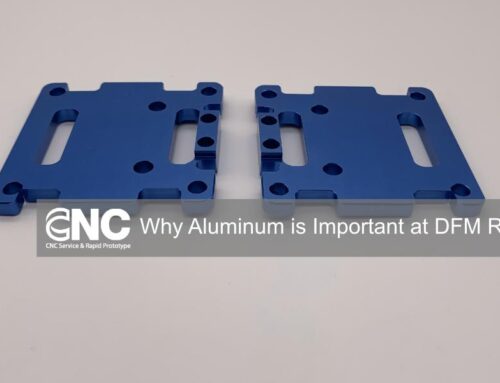

About DFM Rapid

DFM Rapid, a CNC machining shop located in Dongguan, China, boasts 20 CNC milling and turning machines in its shop. Offering CNC rapid prototyping and low-volume CNC machining services for plastic and metal parts, DFM Rapid also provides surface finishes like anodizing and powder coating. For Metal & Plastic parts machined for prototypes or production, get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!