5-Axis CNC Machining stands out as a pivotal manufacturing technique, renowned for its utilization of computer-controlled machine tools to fabricate parts with utmost precision and accuracy. This guide delves into the intricacies of 5-axis CNC machining, exploring its history, principles, applications, and discussing both its advantages and challenges.

A Glimpse into the History of 5-Axis CNC Machining

Originating in the 1950s, the first CNC machines utilized punched tape to store and execute instructions. The evolution of CNC technology has been remarkable, with today’s machines being significantly more advanced and versatile. 5-axis CNC machining, which allows movement along the X, Y, and Z axes, as well as rotation about the X and Y axes, has expanded its usage in recent decades, thanks to advancements in machine tool design and control systems.

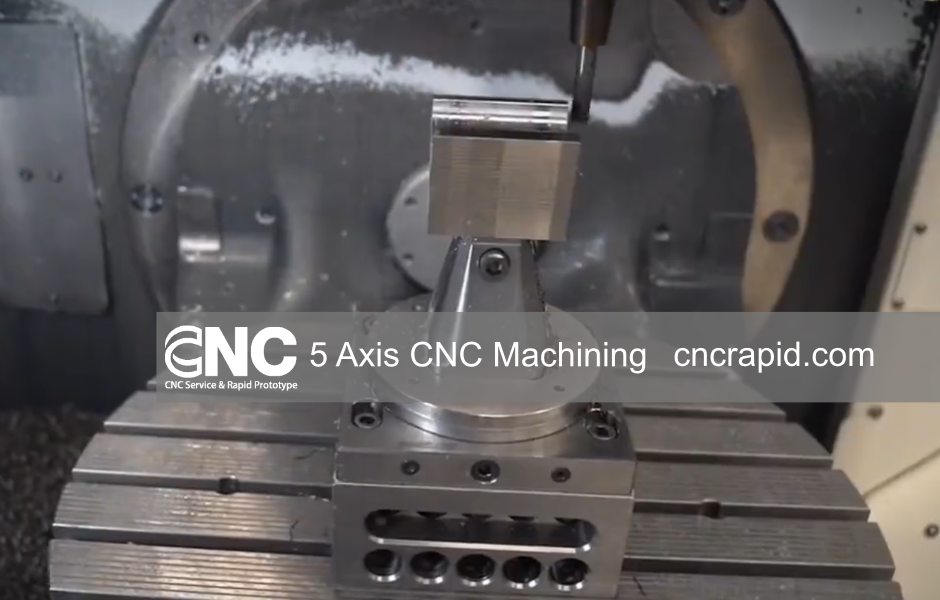

Understanding the Principles Behind 5-Axis CNC Machining

5-axis CNC machining operates with a machine tool capable of five axes of motion. It moves along the X, Y, and Z axes and rotates about the X and Y axes. Controlled by a computer program, it specifies the tool’s movement and orientation, along with the machining operations to be executed. The part being machined is secured by a fixture, adjustable to accommodate the machining of various features and angles.

Diverse Applications Across Various Industries

5-axis CNC machining is employed across numerous industries, including aerospace, automotive, medical devices, and even in the creation of artistic or sculptural objects. It is utilized to manufacture complex aircraft components, engine components, medical implants, and precision components, and to create complex and intricate shapes in artistic objects.

Advantages of Employing 5-Axis CNC Machining

The primary benefits of 5-axis CNC machining include the capability to create complex shapes and features with high precision. Unlike its 3-axis counterpart, 5-axis CNC machining allows rotation about the X and Y axes, offering greater flexibility and access to areas that are difficult to reach. This makes it suitable for producing parts with complex geometries, such as those found in various industries.

Navigating Through the Challenges of 5-Axis CNC Machining

Despite its benefits, 5-axis CNC machining presents challenges, including the requirement for more complex and costly machine tools and the need for specialized programming skills. Additionally, it demands more complex fixtures and tooling to secure and support the part being machined, adding to the overall cost and complexity of the machining process.

Tips and Considerations for Implementing 5-Axis CNC Machining

When considering 5-axis CNC machining, it’s crucial to select the right machine tool, utilize appropriate software, plan machining operations meticulously, and collaborate with an experienced CNC machining provider. These steps ensure that your parts are produced to the highest quality standards and that you successfully incorporate 5-axis CNC machining into your manufacturing processes.

5-axis CNC machining is a potent manufacturing technique, offering the ability to machine complex shapes and features with high precision. While it presents certain challenges, such as the need for complex machine tools and specialized skills, its benefits make it an invaluable tool for manufacturers across various industries. By adhering to the provided tips and collaborating with experienced CNC machining providers, manufacturers can successfully integrate 5-axis CNC machining into their processes.