CNC milling machines have carved out a crucial niche within CNC machining, offering a versatile platform for creating high-precision parts in both small and medium batches, especially those of complex shapes. This method encompasses various techniques, including plane milling, contour milling, and surface milling, while also facilitating drilling, reaming, countersinking, boring, and thread tapping. Let’s delve into the four types of parts that can be crafted using a CNC machine.

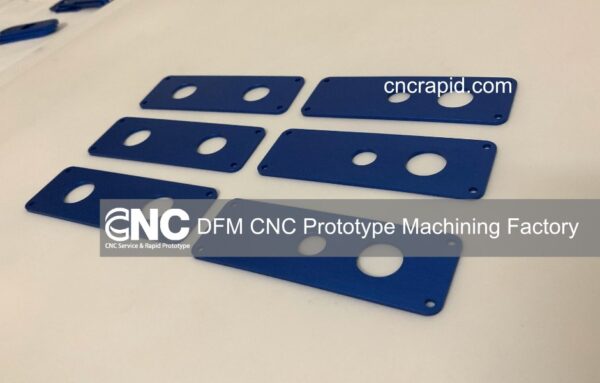

1. Flat parts

Flat parts, characterized by individually machined surfaces that are either flat or can be expanded into a flat shape, constitute a significant portion of parts created on CNC milling machines. These parts, which are relatively straightforward in terms of CNC milling, can generally be processed using 2.5-axis CNC milling machines.

2. Angled parts

Angled parts, where the angle between the machined surface and the horizontal surface continuously varies, are often utilized in the aerospace industry for components like integral beams, frames, rim strips, and ribs. While 4-axis or 5-axis CNC milling machines are optimal for machining these parts, 3-axis CNC milling machines can be used for approximate machining, albeit with slightly reduced accuracy.

3. Curved face parts

Curved face parts, which involve machining surfaces into spatial curved shapes, require point contact during the machining process. Two common methods are utilized for their creation:

- 2.5-Axis Line Cutting Method: This method involves linking only two coordinates during processing, with the other coordinate periodically fed according to a specific line spacing. It is often used for less complex spatial surface parts.

- 3-Axis Linkage Machining: This method, which requires 3-axis linkage, allows for spatial linear interpolation and is commonly used for more complex spatially curved parts.

4. Enclosure/Box type parts

Enclosure or box-type parts, which have more than one hole system and a certain internal cavity or cavity, are machined with a focus on maintaining proportions in length, height, and width. Key considerations during the machining process include prioritizing face milling over hole machining, casting larger holes directly into the blank, and utilizing turning head machining for boxes with large span coaxial holes.

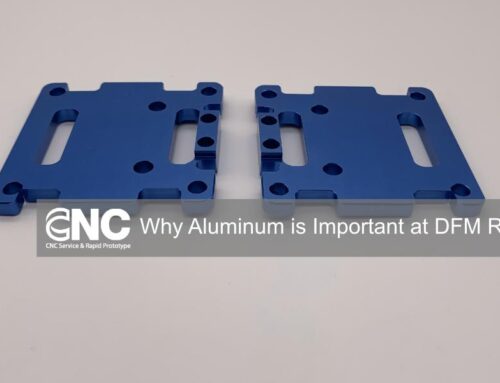

About DFM Rapid

We are a CNC machining China shop in Dongguan. We have 20 CNC milling and turning machines in our shop. We can offer you CNC rapid prototyping and low-volume CNC machining services for plastic and metal parts. Also, surface finish like anodized, powder coating is available. If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!