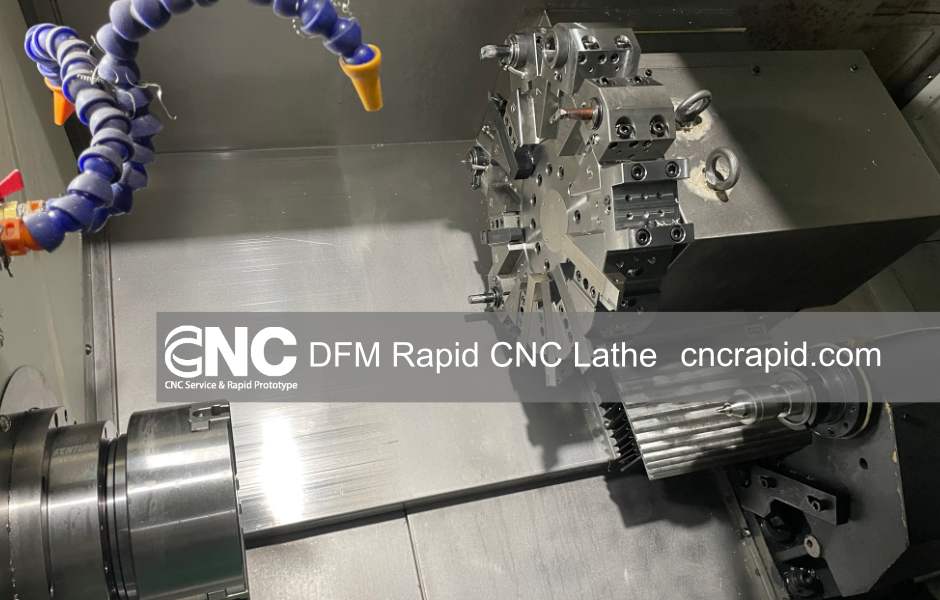

Explore the pivotal role of CNC lathes in achieving flexible automation and their distinct advantages over conventional lathes.

1. Strong Adaptability

Embrace the CNC lathe’s unparalleled adaptability, a key feature that enables effortless transitions between products. By simply altering the processing program and adjusting relevant data within the CNC device, it adapts to new production needs without necessitating hardware modifications to the mechanical and control parts. This adaptability not only caters to the demands of swift product updates and intense market competition but also adeptly addresses the processing challenges of single-piece, small to medium-sized batches, and variable products. The potent adaptability of CNC lathes stands out as its most notable advantage and fuels its rapid development and prevalence.

2. High Machining Accuracy

CNC lathes boast remarkable precision, with the positioning accuracy of small and medium-sized models reaching up to 0.005mm and repeat positioning accuracy hitting 0.002mm. Furthermore, software can be employed for accuracy correction and compensation, achieving even higher precision than the lathe itself. The CNC lathe autonomously executes the predetermined program, eliminating the need for manual intervention during the processing phase and ensuring that the workpiece’s machining accuracy is fully guaranteed by the machine tool. This eradicates operator errors, resulting in workpieces with high precision, consistent dimensions, and stable quality.

3. High Productivity

With their robust structural characteristics, CNC lathes can perform potent cutting with substantial cutting amounts, effectively conserving basic operation time. Additionally, features like automatic speed change, automatic tool change, and other auxiliary operation automations significantly reduce auxiliary operation time, generally resulting in higher productivity compared to ordinary lathes.

4. High Automation, Low Labor Intensity

CNC lathes, operating automatically and continuously according to pre-programmed processing programs, alleviate the operator from engaging in complex and repetitive manual work. Aside from inputting the processing program or managing the keyboard, loading and unloading workpieces, intermediate detection of key processes, and monitoring the machine tool’s operation, the operator’s labor intensity and tension are significantly diminished. Moreover, CNC lathes typically come with enhanced safety protection, automatic chip removal, automatic cooling, and automatic lubrication devices, substantially improving the operator’s working conditions.

About DFM Rapid

We are a CNC machining China shop in Dongguan. We have 20 CNC milling and turning machines in our shop. We can offer you CNC rapid prototyping and low-volume CNC machining services for plastic and metal parts. Also, surface finish like anodized, powder coating is available. If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!