Rapid prototyping services are a set of manufacturing techniques used to quickly produce a physical model or prototype of a product design. The purpose of rapid prototyping is to allow companies to test and validate their designs before committing to full-scale production. Rapid prototyping typically involves the use of advanced technologies such as 3D printing, injection molding, and CNC machining to produce prototypes in a matter of days or even hours, as opposed to the weeks or months it can take to produce prototypes using traditional manufacturing methods. Rapid prototyping services are an essential tool for product development, allowing companies to quickly and inexpensively refine their designs and bring new products to market faster.

Advantages of Rapid Prototyping Services:

- Speed: Rapid prototyping services allow for the production of prototypes in a matter of days or even hours, compared to the weeks or months it can take to produce prototypes using traditional manufacturing methods. This can help companies speed up their product development process and bring new products to market faster.

- Cost Savings: Rapid prototyping can be significantly less expensive than traditional manufacturing methods, as it eliminates the need for expensive tooling and molds. This allows companies to allocate more of their resources to other areas of their business, such as research and development, marketing, and sales.

- Improved Design Accuracy: Rapid prototyping services can produce highly accurate prototypes, allowing companies to identify and resolve design flaws before committing to full-scale production. This can help improve the overall quality of the final product and reduce the risk of costly rework or product recalls.

- Enhanced Collaboration: Rapid prototyping services allow for greater collaboration between designers, engineers, and other stakeholders in the product development process. By quickly producing prototypes, teams can work together to refine designs and resolve any issues in real-time.

- Access to Advanced Technologies: Rapid prototyping services utilize a range of advanced technologies, including 3D printing, injection molding, and CNC machining, allowing companies to choose the technology that best suits their specific needs and requirements.

What is CNC Rapid Prototyping?

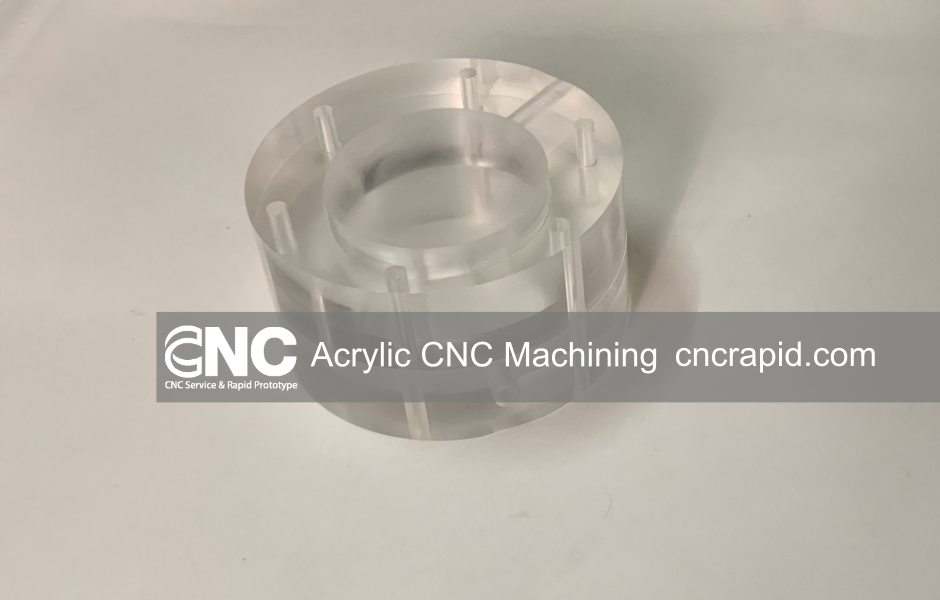

CNC Rapid Prototyping Services are a type of rapid prototyping service that utilizes computer numerical control (CNC) machining to produce prototypes. CNC machining is a process that uses computer-controlled equipment to shape and cut materials into precise shapes and sizes. CNC rapid prototyping services are commonly used to produce high-quality, functional prototypes of complex, precision parts, including mechanical components, electronic enclosures, and consumer products. These services are ideal for companies that require prototypes that closely resemble the final product and need to be tested for fit, form, and function. The use of CNC machining in rapid prototyping allows for the production of prototypes with fine details, tight tolerances, and high levels of accuracy, making it an ideal solution for a wide range of product development applications.

Advantages of CNC Rapid Prototyping Services:

- High Accuracy and Precision: CNC machining is capable of producing prototypes with high accuracy and precision, making it ideal for creating complex shapes, tight tolerances, and fine details.

- Flexibility: CNC machining can work with a wide range of materials, including metals, plastics, and composites, allowing for a high degree of flexibility in the prototyping process.

- Short Lead Times: CNC rapid prototyping services can produce prototypes in a matter of days or even hours, helping companies speed up their product development process and bring new products to market faster.

- Cost-Effective: CNC rapid prototyping services can be cost-effective, especially when compared to traditional prototyping methods, as it eliminates the need for expensive tooling and molds.

- Durable and Functional: CNC machined prototypes can be used for functional testing and evaluations, as they are made of durable materials and can withstand harsh environments.

- High-Quality Finish: CNC machining can produce prototypes with high-quality surface finishes, making them ideal for parts that will be seen by consumers, such as consumer electronics and other products.

Why Choose DFM Rapid?

We specialize in providing top-notch CNC Rapid Prototyping Services. Our mission is to help businesses and organizations bring their products to market faster by utilizing the latest in CNC machining technology. Our team of experts is dedicated to providing high-quality prototypes that meet the specific requirements of our clients. With years of experience in the industry and a commitment to customer satisfaction, we are the go-to choice for businesses that require the most accurate and precise prototypes. Our CNC Rapid Prototyping Services allow for the production of prototypes with fine details, tight tolerances, and high levels of accuracy, making it an ideal solution for a wide range of product development applications.

Rapid prototyping services China. Our rapid prototyping service helps designers, engineers, and manufacturers develop and evaluate prototype parts quickly and economically.

|

|

CNC machining is ideal for making high-quality rapid prototypes from plastic or metal without investing in expensive tooling. Your parts will achieve tighter tolerances with better surface finishes than with other prototyping methods. We can also machine all the features needed for a fully functional part, including tapped and threaded holes and precisely flat surfaces.

We have over 25 CNC mills, lathes and EDM machines in our factory for all your CNC needs. We also have a multilingual support team to ensure your product development journey is smooth and worry free. Learn more about our CNC machining services.

Advantages Of Making A Prototype

- Show your customers and investors a physical model of your product.

- Demonstrate the appearance, dimensions and features of your product.

- Test the market with your product before production.

- Save time and money by identifying and reducing design flaws.

- Improve and streamline the production process

- Create multiple versions with different colors, surface textures and finishing processes.

Contact us today to learn more about how we can help you bring your products to life with our CNC Rapid Prototyping Services.

Get in Touch

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please include the following information so that we can provide an accurate quote:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!