Aluminium is silvery gray metallic, it is soft, lightweight, non-magnetic, and ductile. Aluminum offers excellent machinability, durability, low weight, and low cost for a variety of CNC Turning Aluminium parts in automotive, machinery, medical, aerospace, electronics, and other industries.

Designers and engineers frequently choose aluminium for CNC Turning parts. That makes sense. This all-purpose metal has been proven to offer:

- Excellent machinability

- High strength

- Hardness

- Heat tolerance

- Corrosion resistance

- Chemical resistance

- Electrical conductivity

- Low weight

- Low cost

- Overall versatility

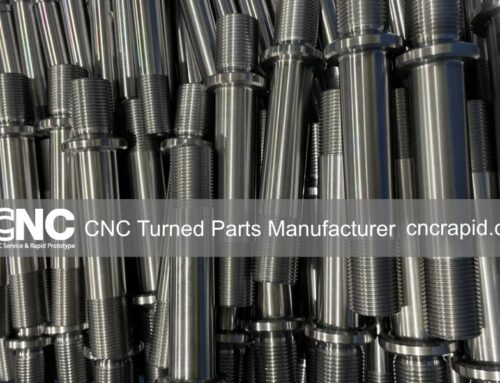

Our CNC turning center for aluminum components exclusively consists of state-of-the-art CNC turning machines and skillful engineers to satisfy our customers’ requirements. Whatever the complexity of the aluminum part to be turned, we optimize manufacturing costs by respecting deadlines and quality of manufacture. We have the capacity to meet your prototype or production demands. Indeed, our quality and the customer-first process will ensure you receive every order to specification.

Advantages Of Our CNC Turning Aluminium Services:

- Wide Applications

Aluminum Medical parts, Automotive parts, Machinery components, Telecommunication parts, Bicycle parts, Transmission parts and suspension parts, Hardware fittings, Blocks, housings, and plates. - Various Quality Aluminum Materials

Aluminum 2024, Aluminum 5052, Aluminium 5083, Aluminum 6061, Aluminum 6063, Aluminium 7050, Aluminium 7075. - Multiple Surface Finishes

Zinc Plating, Nickel, Chrome, Dyeing, Hard anodizing, Polishing, Sandblasting, Painting, Powder Coating, etc. - Advanced Turning Machines

Our multi-axis CNC turning centers meet the highest demands for precision and productivity, it’s possible to turn very complex aluminum parts. - Cost-effective Production

Under the premise of guaranteeing high-quality products, the production time is minimized to achieve unbeatable value for money.

Our CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production.

Why DFM Rapid?

We are a CNC machining factory in Dongguan, China. We have 20 CNC milling and turning machines in our shop. We can offer you CNC rapid prototyping and low-volume CNC machining services for plastic and metal parts. From 1 to 10000+ parts.

Our team listens to your project demands throughout the process, from consultation to after-sales. Our engineers and project leads have sufficient manufacturing know-how to handle your projects efficiently.

Our CNC machines can maintain a high-quality level whether you want one piece or one hundred. Our advantage is providing high-quality manufacturing solutions and quickly turning them into reality.

Why choose CNC machining?

CNC machining is a fast, precise, and universal machining method, suitable for manufacturing any quantity of product orders, without the need to make a mold, that is economical.

What materials can be machined?

Common metal materials on the market such as stainless steel, mild steel, aluminum, copper, brass, magnesium alloy, titanium alloy can be used for CNC machining. Plastics can also be CNC machined. Such as acetal, POM, ABS, Polycarbonate, PMMA, PEEK, and more.

What is the maximum part size your machine can handle?

Our maximum part size is 2000 x 600 x 600 mm, 78.7 x 23.6 x 23.6 in

What is the tolerance range that CNC machining can do?

It depends on the dimension of the parts. Normally our standard of tolerance is from +/-0.01mm to +/-0.15mm.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!