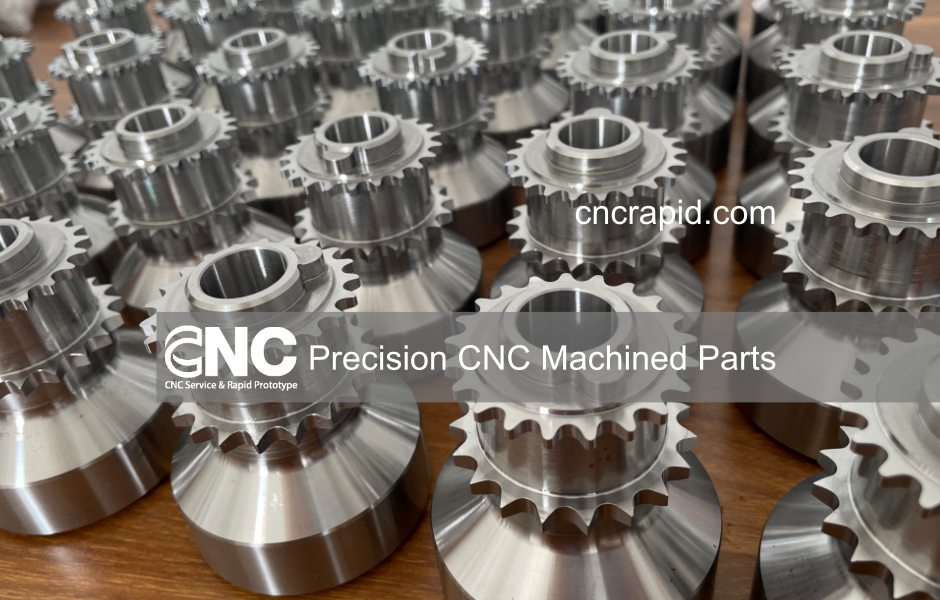

CNC machining is a versatile manufacturing process that uses computer-controlled machines to produce precise and intricate parts. CNC machining is a subtractive manufacturing process that involves cutting away material from a solid block to create a desired shape. The process is highly precise and allows for the production of complex and intricate parts with a high degree of accuracy. CNC machining is widely used across a variety of industries, from aerospace and automotive to medical devices and consumer products.

Types of CNC Machines and Their Uses

There are several types of CNC machines available, each with its own set of strengths and weaknesses. Some of the most common types of CNC machines include:

- CNC mills: used for a variety of machining tasks, including drilling, boring, and milling

- CNC lathes: used for turning cylindrical parts and producing circular cross-section cuts

- CNC routers: used for cutting and shaping materials like wood, plastic, and composites

- CNC plasma cutters: used for cutting metal and other materials with a high-temperature plasma arc

Benefits of CNC Machining

CNC machining offers several advantages over traditional manufacturing methods, including:

- Precision: CNC machines are highly precise and can produce parts with tight tolerances, ensuring that your final product meets your specifications

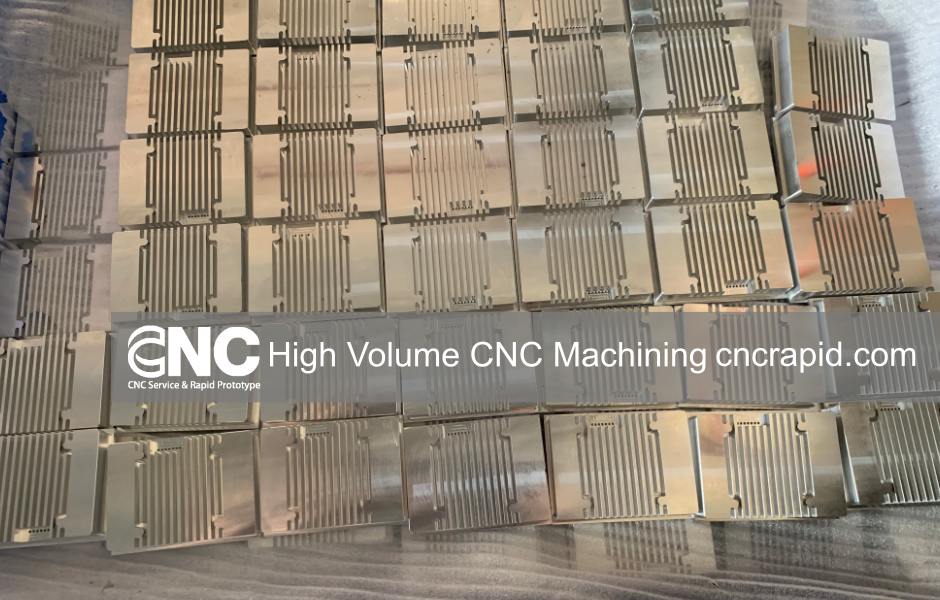

- Speed: CNC machines can produce parts quickly and efficiently, reducing lead time and increasing productivity

- Consistency: CNC machining ensures consistent quality, as the machine follows a set of programmed instructions every time

- Customization: CNC machining can be easily programmed to produce unique and complex parts, making it ideal for customization and one-of-a-kind products

Quality Control and Assurance in a CNC Machining Factory

Quality control is a critical component of the CNC machining process. Look for a CNC machining factory that has a robust quality control process in place, including regular inspections, testing, and documentation of their work. This will ensure that your parts are produced to the highest standards and meet your specifications.

Customization and Design Services

A good CNC machining factory should also offer customization and design services. This allows you to work with the factory to create parts that are tailored to your specific needs and requirements. The factory should have a team of experienced engineers and designers who can help you bring your ideas to life.

Capabilities and Tolerances

When choosing a CNC machining factory, it’s important to understand their capabilities and tolerances. This includes the types of machines and equipment they have, as well as their expertise in machining specific materials and producing parts to precise tolerances. Make sure the factory you choose can meet your specific requirements and deliver high-quality parts.

Applications of CNC Machined Parts in Various Industries

CNC machined parts have a wide range of applications in various industries, including:

- Aerospace: CNC machined parts are commonly used in the aerospace industry for the manufacture of aircraft components, such as engines and landing gear.

- Automotive: CNC machined parts are used in the automotive industry for the production of engines, transmission parts, and suspension components.

- Medical: CNC machined parts are used in the medical industry for the manufacture of surgical instruments, prosthetics, and implants.

- Electronics: CNC machined parts are used in the electronics industry for the production of computer components, such as hard drives and circuit boards.

- Consumer Goods: CNC machined parts are used in the consumer goods industry for the production of a wide range of products, from toys to appliances.

CNC machining has become an increasingly popular choice for manufacturers in these industries due to its accuracy, consistency, and ability to produce parts with complex geometries and intricate details. With the right CNC machining factory, it’s possible to produce high-quality parts that meet the specific needs and requirements of each industry.

Choosing the Right CNC Machining Factory

Choosing the right CNC machining factory is critical to the success of your project. When choosing a factory, consider the following factors:

- Capabilities: Make sure the factory you choose has the right equipment and expertise to meet your needs.

- Quality: Look for a factory that has a strong focus on quality control and assurance.

- Lead Time: Consider the factory’s lead time and make sure they can deliver your parts in a timely manner.

- Cost: Get quotes from several factories and compare their prices to find the most cost-effective option.

- Customer Service: Look for a factory that offers good customer service and is easy to work with.

CNC machining is a versatile and precise manufacturing process that offers a wide range of benefits. When choosing a CNC machining factory, it’s important to consider their capabilities, quality control, lead time, cost, and customer service. With the right factory, you can ensure that your CNC machined parts are of the highest quality and meet your specific needs and requirements.

Why Choose DFM Rapid?

We are proud to be a leading CNC machining factory, with a team of experienced machinists and advanced CNC machines. Our focus on quality and customer service sets us apart from the competition, and we are dedicated to delivering the highest-quality CNC machined parts to our customers. Whether you’re looking for a partner for a one-time project or a long-term manufacturing relationship, we have the expertise and capabilities to meet your needs.

Our extensive experience in CNC machining and our commitment to using the latest technologies ensure that we can handle any project, big or small. We specialize in a wide range of materials, from plastics and metals to composites, and can accommodate tight tolerances and complex geometries with ease.

We understand the importance of meeting deadlines and delivering parts that meet your specifications, and we take pride in our ability to deliver results that exceed our customers’ expectations. Our quality control processes are rigorous and thorough, ensuring that every part we produce is of the highest quality.

Our CNC machining factory is committed to delivering the highest-quality CNC machined parts to our customers. With our expertise, advanced CNC machines, and dedication to customer service, we are confident that we can meet the needs of any project. Contact us today to learn more about what we can offer and how we can help bring your ideas to life.

Contact us

If you need Metal & Plastic parts machined for prototypes or production, please feel free to get a quote online.

Or email us at [email protected] to tell us About Your Project

Please try to include the following information:

- Part Name

- 3D Drawing

- Quantity

- Material

- Tolerance Range

- Surface Finish

Thank you for your time!